Michigan Stabilized Construction Access Road

Michigan is home to Detroit, known as the "Motor City," which left a lasting mark on modern culture at the turn of the century. In 1908, Henry Ford introduced the Model T and the assembly line production method to the automotive industry, enabling lower-cost manufacturing and broader adoption of motor vehicles. Besides the manufacturing industry, Michigan is also a central agricultural hub of dairy and crops.

Michigan has the longest freshwater coastline of any U.S. state and is bordered by four of the five Great Lakes. Lake Superior, located in the northern region, holds approximately 10% of the world's freshwater reserves. The proximity to these precious water resources prompted proactive measures to protect water quality, ensuring the lakes and rivers remained free from excessive sedimentation and pollution.

Michigan Department of Environment, Great Lakes, and Energy (EGLE)

Formerly called the Michigan DEQ, the Michigan Department of Environment, Great Lakes, and Energy (EGLE) regulates and oversees the quality of water across the state. Due to the state's primary freshwater resources, it has taken proactive steps to establish regulations that preserve water quality. The state had already implemented the Water Resources Commission Act ("Act 245") in 1929 to protect water quality when the Federal Clean Water Act was passed in 1972. Further regulation was passed to, and Part 91, Soil Erosion and Sediment Control, of the Natural Resources and Environmental Protection Act (NREPA) is a primary state statute for managing soil erosion and sedimentation associated with construction and other earth change activities. Part 91 requires the issuance of Soil Erosion and Sediment Control (SESC) permits before undertaking earth change activities that disturb one or more acres of land or are within 500 feet of a lake or stream. Part 91 of NREPA is Michigan’s primary legal framework for soil erosion and sedimentation control on earth change activities.

Part 91 SESC Permits

Part 91, Soil Erosion and Sediment Control permits (SESC permits or "Part 91 Permit") are administered and enforced by localities such as county and local agencies. Counties are required to administer and implement Part 91, including the establishment of a County Enforcing Agency (CEA). In addition, many cities, townships, and local governments have elected to establish a Municipal Enforcing Agency (MEAs), which will assume responsibility for issuing SESC permits and ensuring compliance with Part 91 in their jurisdiction.

The application process involves creating an SESC plan. The SESC plan includes various details about the projects, including a map, the distance between earth disturbances and water features, a description of site drainage, a schedule of earth-disturbing activities, a description and location of all SESC measures, and a maintenance program for SESC measures.

Permit-by Rule

The Federal Clean Water Act established the National Pollutant Discharge Elimination System (NPDES) permit program, which is commonly regulated under three types of permits: Construction, Industrial, and Municipal. The Michigan EGLE integrated the NPDES Permit program under a "Permit-by-Rule" process to prevent contractors and site operators from needing to obtain two stormwater permits. For construction projects that disturb between one and five acres of land and have a point source stormwater discharge to waters of the state, NPDES stormwater coverage is provided automatically under Michigan’s Permit-by-Rule once the operator obtains the required SESC “Part 91” permit or APA status from the appropriate enforcing agency. For sites disturbing five or more acres of land, the operator must also submit a Notice of Coverage (NOC) to the EGLE Water Resources Division (WRD) along with a copy of the SESC plan, map, and applicable fee. EGLE's Water Resources Division (WRD) uses an online portal, called MiWaters, for all document submissions related to stormwater permits. The portal is used to submit permit applications, discharge reports, and supporting documents, as well as to receive real-time updates from EGLE, enabling contractors to make changes quickly and address potential permit violations.

Michigan Stabilized Construction Access Road Specification (S53)

One of the first SESC measures, or Best Management Practices (BMPs), used on any construction site is the Access Roads or Stabilized Construction Access. The purpose of a Stabilized Construction Access Road is to prevent the migration of sediment from disturbed areas onto roadways by vehicle traffic. If sediment is deposited onto paved or impermeable roadways, rain events can wash the debris into storm drains or surface waters. The Access Road, also called Exit Road or Stabilized Construction Access, should be installed at all points where vehicular traffic exits the job site. Any roadways leaving the site that are not stabilized should be blocked to prevent construction traffic from exiting the site.

Various organizations and departments have produced guidebooks and manuals with specifications for Stabilized Construction Access or Access Roads, commonly used in the state of Michigan. The EGLE links to these other standards and guides to help contractors and engineers plan a construction project. Each of these guidebooks uses a different name to refer to the Access Road SESC measure.

EGLE BMP Access Road

The EGLE BMP Manual includes the Access Road Design Reference in the Surface Water section of their website. The Access Road is constructed of 2-3 inch diameter washed aggregate, stone, or crushed concrete that is laid over a non-woven geotextile fabric. The Design Reference recommends using angular or crushed aggregate to increase pore space, enhance longevity, and improve effectiveness. The stone size should be increased for heavy equipment, and the stone size should be such that the aggregate is not wedged between dual-tire vehicles. The minimum dimensions are 50' in length and 10 feet in width, with a wider turning radius. The depth of the Access Road should be at least 6 inches of 2-3 inch stone, but should be deeper if larger stones are used. The area should have drainage and measures to contain runoff within the job site.

The contractor is required to inspect the Access Road daily for signs of failure while it is in use. When sediment begins tracking onto the roadway, the rock may have become rutted, and stone could be migrating into the sub-base. The solution is to repair the failures and immediately sweep the roadway to prevent sediment from entering storm drains. When repairs are frequently required, contractors may opt to increase the length of the entrance or install a tire wash with proper drainage (eg, Sediment Basin).

Tire washing is mentioned as a way to improve effectiveness, as well as the use of "drive-on" corrugated or ribbed steel plates. These techniques are used to dislodge additional sediment from tires. Proper drainage should be installed to prevent runoff from carrying sediment-laden water into the roadway, especially when tire washing is implemented.

DTMB SESC Guidebook (S53) Stabilized Construction Access

The Department of Technology, Management, and Budget SESC Soil Erosion and Sedimentation Control Guidebook includes specifications for the (S53) Stabilized Construction Access. This Guidebook is used to inform the State of Michigan construction projects. The stated purpose of the (S53) Stabilized Construction Access is to minimize tracking of sediment onto public roadways and to minimize disturbance of vegetation. The Stabilized Construction Access should be installed at all points where construction traffic leaves the site, and all vehicles must be routed to use the rock ingress/egress. The Guidebook states that the scope of work for installation should fall to the site clearing or excavating contractor and that the Stabilized Construction Access area should be cleared of woody vegetation before commencing site grading. The minimum dimensions recommended in this guide are 50' in length and 12' in width; however, for a residence lot, the minimum Stabilized Construction Access length may be reduced to 30'. The depth mentioned here is 8" of 2-3" crushed rock. The entrance should be inspected regularly, as well as after each rain event, and the stabilized entrance should be repaired by adding rock as needed.

A wash rack may be necessary if the Stabilized Construction Access (S53) is insufficient for cleaning vehicle tires. The tires should be washed over a stabilized area and before other techniques, such as the rock-stabilized entrance. Any sediment tracked onto roadways must be removed immediately and returned to the construction site to prevent it from washing down a storm drain or into nearby surface waters.

MDOT SESC Manual Gravel Access Approach

The MDOT Soil Erosion and Sediment Control Manual includes specifications for highway and public roadway projects. The technique employed here is known as the Gravel Access Approach, designed to minimize the tracking of loose materials from the construction site onto public roadways. The Manual recommends coarser aggregate, which is more effective, and regular replenishment of aggregate when the Gravel Access Approach is no longer preventing tracking.

MACDC SESC Manual 28. Stone Construction Access

Lastly, the Michigan Association of County Drain Commissioners creates the MACDC SESC Manual, which mentions the 28. Stone Construction Access. The goal of this technique is to minimize fugitive dust and soil tracking onto roadways. The minimum dimensions listed are 50' long and 12' wide or as required to match the specific job site. The optional Diversion Ridge may be needed to contain runoff onsite if the exit grade is toward the roadway. The specifics of the entrance are to be specified by the engineer.

FODS Modern Stabilized Construction Entrance

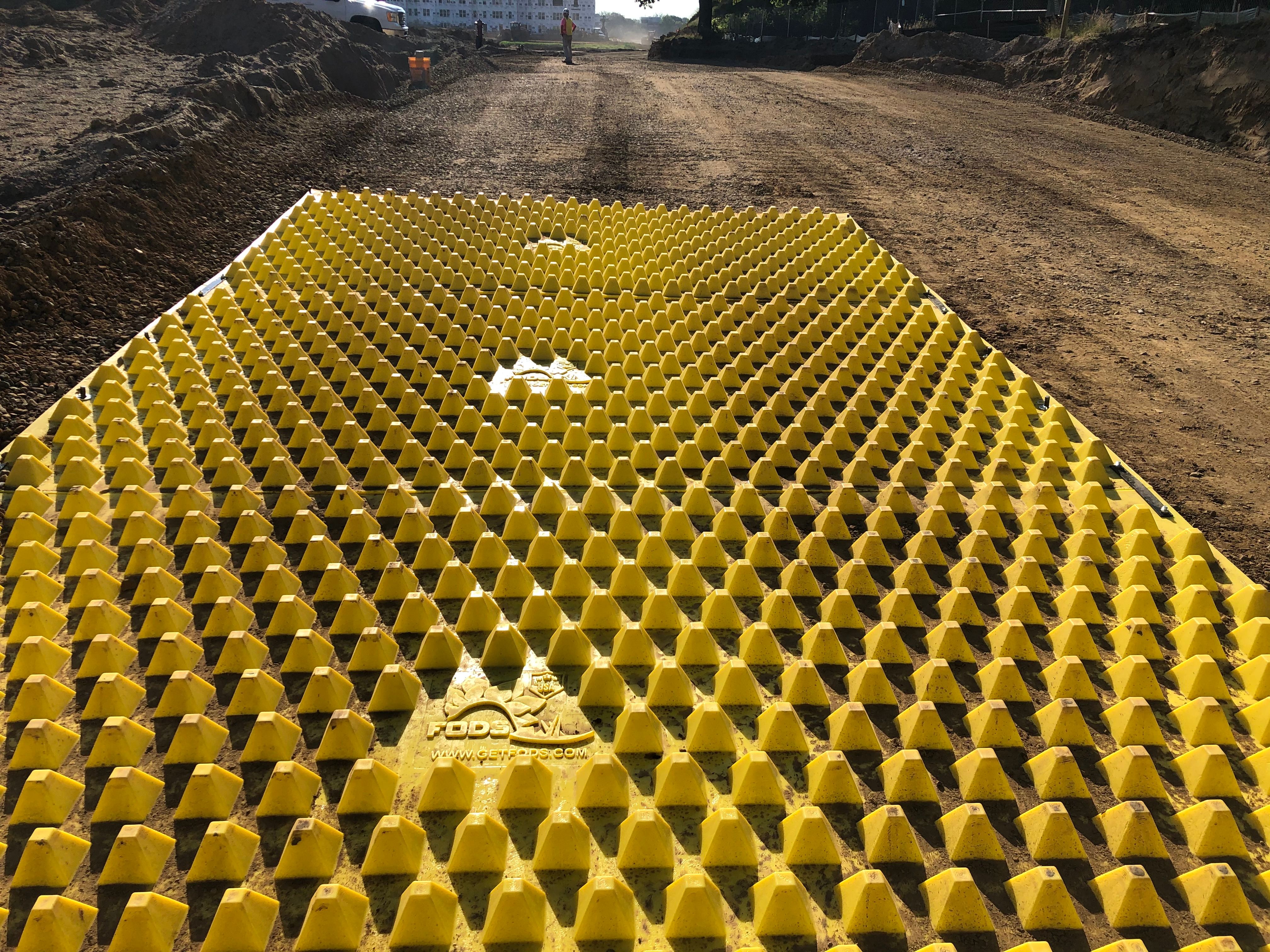

The FODS Trackout Control Mat System is designed to stabilize construction and industrial site ingress and egress points, minimizing the tracking of sediment onto adjacent roadways. This approach serves as an alternative to the various construction access and stabilization methods referenced in manuals and guidebooks, such as access roads, stabilized construction entrances, gravel access approaches, and stone construction access points.

The Stabilized Construction Access pads are a modern and highly effective solution to job site trackout. The system is composed of durable high-density polyethylene (HDPE) mats, which are formed into pyramid shapes that function similarly to the rough edges on crushed stone.

Highly Effective

The pyramids deform vehicle tires and open tire treads, allowing sediment and debris to break loose. Since the vehicle tires ride on the tops of the pyramids, the base of the pyramids mimics the voids or pores in a traditional Access Road. The system has been demonstrated to reduce street sweeping by 59% on high traffic projects.

Easily Maintained

The mats can hold up to 2.5" of sediment before vehicle tires come into contact with previously deposited debris. The system is easily maintained onsite without requiring additional materials through quick and simple cleaning methods, including a skid steer with a broom attachment, a powered sweeper, a street sweeper, or manual cleaning with a FODS shovel.

Increased Safety

Because the system does not aggregate any size vehicles, it can be used, and the system does not introduce the risk of the aggregate becoming wedged in dual-tire vehicles. The rockless system also reduces the risk of aggregate migrating to active roadways, which makes the system ideal for highway and urban environments.

Durable & Reusable

The system is reusable and portable, allowing contractors to reuse it in multiple locations during subsequent job phases and continue using it on the next project. The mats are designed for heavy-duty use and have an expected service life of 10 years or more, allowing contractors to stay compliant and reduce costs.

Additional Resources:

EGLE Individual BMPs - Access Road

DTMB SESC Guidebook - (S53) Stabilized Construction Access

MDOT Manuals and Guidelines - Soil Erosion and Sedimentation Control Manual - Gravel Access Approach

MACDC SESC Manual - 28. Stone Construction Access