Landfill & Industrial Sites

As industries evolve and populations grow closer to Industrial zones, the responsibility to maintain safety, efficiency, and environmental compliance has never been greater. Facilities such as landfills, recycling plants, transfer stations, stone quarries, and manufacturing plants must balance productivity with regulatory obligations under the Clean Water Act and the National Pollutant Discharge Elimination System (NPDES). One of the most visible and persistent compliance challenges on these sites is vehicle trackout—the mud, sediment, and contaminated debris carried from facilities onto surrounding roadways.

0/9

TRADITIONAL SOLUTIONS

Site trackout is more than a nuisance. When left neglected and unmanaged, it creates safety hazards, increases roadway maintenance costs, accelerates wear on equipment, and exposes operators to fines and or penalties under NPDES permits and state-level stormwater pollution prevention requirements. With federal and state regulators increasingly scrutinizing stormwater compliance, industrial operators need solutions that are reliable, durable, and cost-effective over the long term.

For decades, industrial operators have relied on steel grates, rumble strips or stabilized construction entrances made of large aggregate or stone. While simple in concept, these steel or gravel-based systems have several serious drawbacks in landfill and industrial settings:

- High maintenance burden – Rock entrances require continual “refresh or top dressing” with additional aggregate to maintain effectiveness. Heavy truck traffic quickly embeds sediment into the stone, reducing its cleaning ability and requiring frequent replacement.

- Operational Limitations & inflexibility – Gravel pads are a fixed in place sunk cost solution. They cannot be relocated easily as facilities change or site traffic patterns evolve, which is common in dynamic environments such as landfills or mining operations.

- Limited installation options – Rock cannot be installed effectively on milled, paved, or concrete surfaces, which are common around transfer stations, processing plants, and recycling facilities.

- Hidden costs – Sourcing, hauling, spreading, and disposing of rock creates recurring expenses that add up significantly over the life of an industrial site.

- Environmental impact – Gravel introduces its own source sediment into the stormwater system, compounding the very problem it is meant to mitigate.

These limitations have led many industrial operators to turn to FODS as the alternative that is easier to maintain, more adaptable, and better aligned with modern compliance standards.

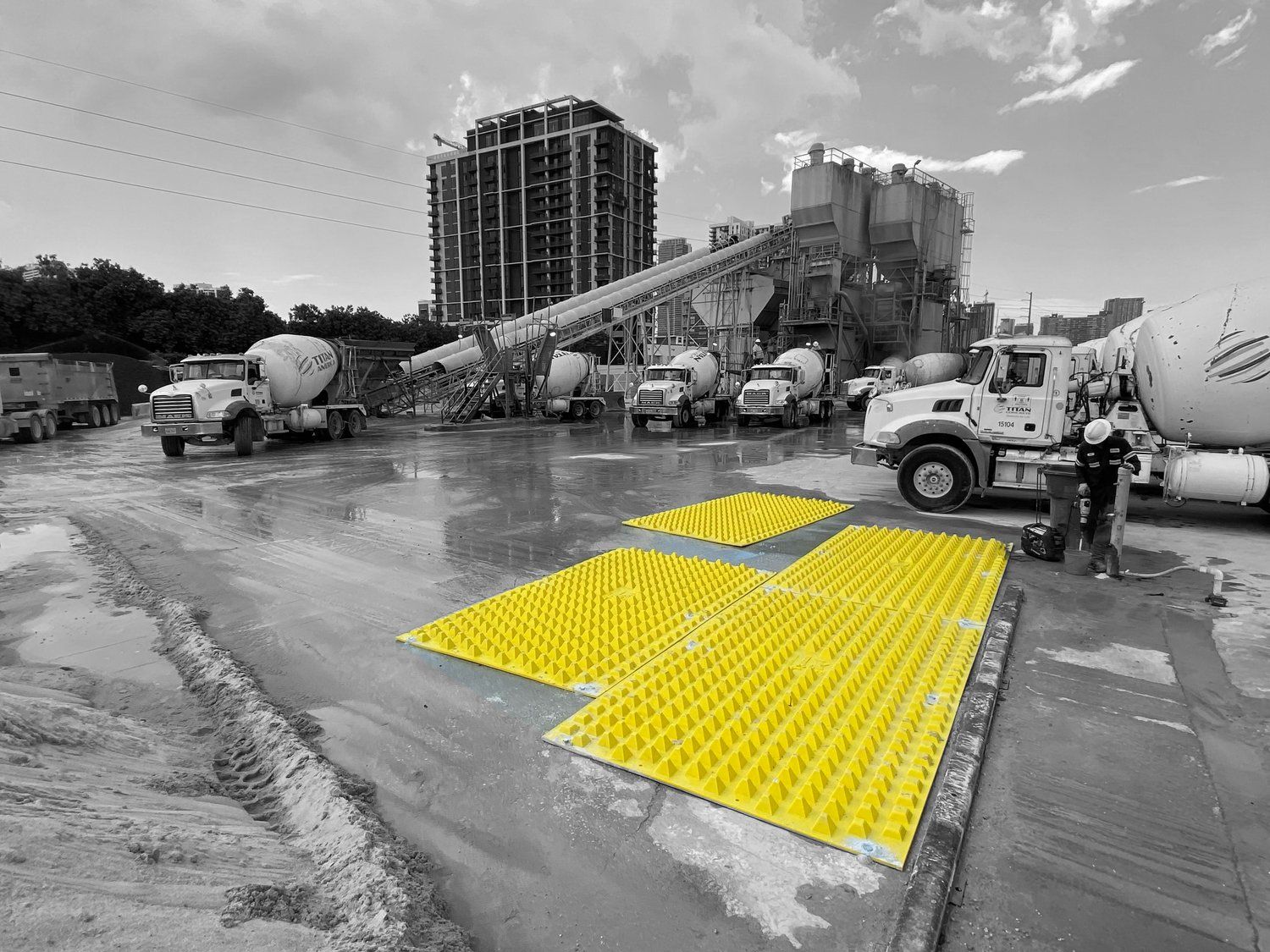

FODS MODERN INDUSTRIAL SITE TRACKOUT CONTROL SYSTEM

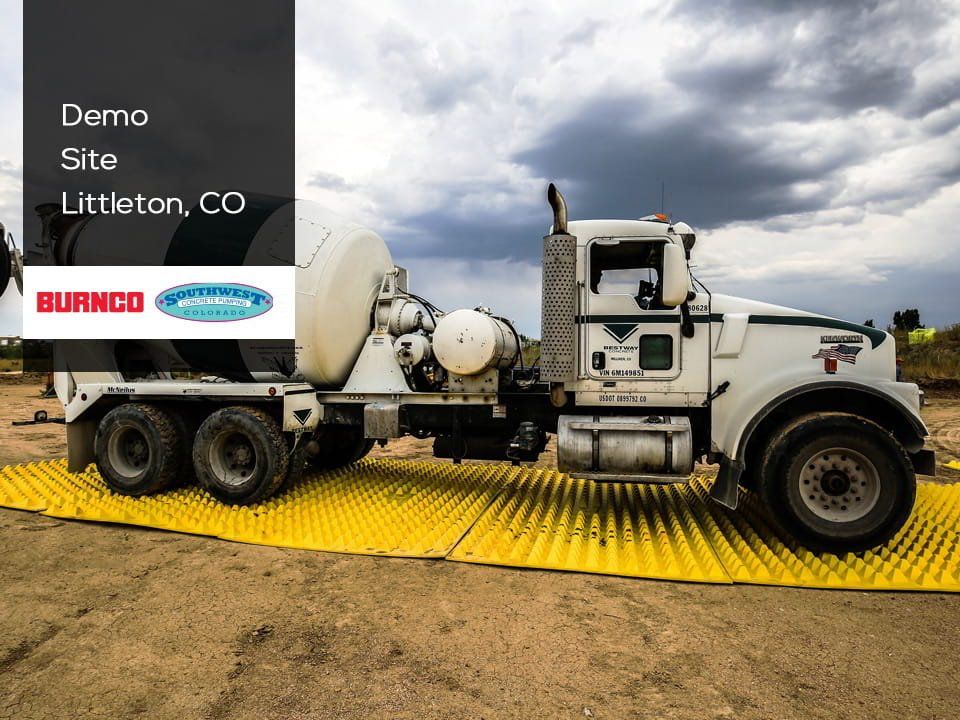

The FODS Trackout Control System is the next generation of Best Management Practice (BMP) for vehicle trackout. Unlike disposable aggregate pads, steel grates, and rumble strips, FODS mats are engineered, reusable, and built for both permanent and semi-permanent industrial applications.

Key Performance Features

- Superior trackout reduction: Independent studies have shown that FODS Rockless Trackout Control System reduces required street sweeping by 59% - 80%, offering clear cost savings and compliance advantages over traditional solutions.

- Durability under heavy loads: With a PSI of over 1000, each pyramid-shaped cleat on the mats is engineered to withstand 20,000 lbs. of direct load before even dimpling and ultimate crush strength of over 50,000lbs per pyramid, ensuring performance under the heaviest haul trucks, compactors, loaders, and highway-legal vehicles.

- Long service life: Constructed from ultra-durable, high-density polyethylene (HDPE), FODS mats are designed for 10+ years of harsh environment use, even in extreme climates and high-traffic conditions.

- Portability and adaptability: Unlike gravel, FODS mats can be installed, anchored, relocated, and maintained without heavy equipment. This makes FODS ideal for permanent and semi-permanent applications which require effective sediment and debris containment. FODS are equally effective on pavement, asphalt, concrete, or directly on grade.

- Environmental responsibility: The mats eliminate the need for mining, quarrying, transporting, and ultimately disposing of stone, dramatically reducing lifecycle carbon emissions impact while also preventing secondary sediment pollution from gravel itself.

Advantages Of FODS On landfill & industrial Construction Projects

Landfills & Transfer Stations

Waste handling sites face a constant stream of inbound and outbound traffic, from collection trucks to heavy compactors. Contaminated soils, debris, and leachate present heightened environmental risks. FODS provides a stable, cleanable, and relocatable trackout control solution at both temporary and long-term access points.

Mining & Quarry Operations

Open-pit mines and stone quarries involve continuous traffic of haul trucks, loaders, and support vehicles. Sediment-laden soils and dust are inevitable, but uncontrolled trackout can result in violations and complaints from surrounding communities. FODS offers a rugged system that endures heavy loads while reducing sediment export to nearby public roadways.

Manufacturing & Processing Facilities

Industrial facilities that handle chemicals, aggregates, or raw materials often generate fine sediments and potentially hazardous particles. Because these sites are typically semi-permanent or permanent, a long-life solution like FODS is critical. The mats provide compliance assurance without the perpetual maintenance costs of gravel pads.

Recycling & Material Recovery Plants

Recycling centers and material recovery facilities deal with diverse loads and traffic volumes. FODS mats, anchored over pavement or directly on grade, give operators flexibility as site layouts evolve, while ensuring stormwater compliance at all exit points.

Regulatory Alignment: NPDES and Beyond

Industrial operators are subject to specific NPDES permit requirements that go beyond general construction site standards. While construction projects typically focus on sediment, many industrial operations involve toxic or hazardous materials that pose risks to aquatic life and public health. Regulators therefore demand highly effective solutions to prevent material migration off-site.

Key considerations include:

- Permanent compliance measures – Unlike temporary construction projects, industrial operations require BMPs that function reliably year after year.

- Adaptability to changing operations – Facilities must reconfigure access routes as production scales or material flows shift.

- Compatibility with multiple substrates – Many industrial access points are paved or built on concrete aprons; solutions must function equally well on hardscape and soil.

The FODS Trackout Control System is engineered to directly addresses these requirements, enabling operators to demonstrate compliance in an approved and visible manner and reduce liability exposure under both federal and state stormwater pollution prevention plans (SWPPPs).

Cost Efficiency & ROI

The benefit and cost savings of transitioning your site Trackout Control Method to FODS is clear and measurable:

- Reduced aggregate costs – No more sourcing, hauling, or replacing stone.

- Lower maintenance costs – With nearly 60% fewer street sweeping events required, operators see immediate savings.

- Fewer violations and fines – By staying compliant with NPDES permits, operators avoid costly penalties.

- Extended service life – A 10+ year lifespan spreads the cost of ownership across many projects or operational phases.

- Relocatable assets – Unlike stone, FODS mats can be reused across multiple sites or reconfigured as facility layouts change.

When calculated over the lifespan of a landfill, mine, or processing facility, FODS mats consistently outperform gravel pads in total cost of ownership.

Sustainability & Corporate Responsibility

In addition to regulatory compliance and cost savings, by incorporating recycled material in the production of the mats, FODS mats align with broader sustainability goals. By eliminating the need for constant stone deliveries, operators reduce emissions from quarrying and trucking. The HDPE construction is recyclable, allowing the mats to be repurposed at the end of their service life. This makes FODS not only a compliance tool but also a sustainability asset that supports corporate environmental responsibility commitments.

A smart ROI, low long term cost, and meets minimum entrance width requirements

Provides an anchored compact stable exit/entrance for construction traffic

Easily and rapidly installed in under 30 minutes, moved, removed, relocated and reused

Alleviates risk management associated with construction entrances

Helps prevent tracking of mud onto roadways, reduces fugitive dust, sediment erosion and storm water runoff

Is versatile and be anchored to any substrate including concrete, pavement, asphalt, etc.

Longevity: Designed for over ten years of use.