Alaska Stabilized Construction Exit and Vehicle Track-Out BMPs

The vast Alaskan Tundra makes up the largest and the most sparsely populated state in America. Alaska’s 660,000 square miles of land area is bordered by the Arctic Ocean in the North, the Pacific Ocean in the South and Canada’s British Columbia in the east. Alaska’s sprawling coastline is longer than all other U.S. states’ coastline combined. The Yukon River which is fed by thousands of glacial and snow melt mountain streams and runs nearly 2,000 miles into the Bering Sea. The storm water basin area of the Koyukuk River is 316,000 square miles across the heart of Alaska and has been used for transporting miners in the late 1800s during the Klondike Gold Rush.

Alaska is home to vast array of wildlife including the wolverine, moose, caribou, and five species of Pacific salmon. The purity of the storm water system of the state is pivotal to maintaining the health of this habitat as well as the fishing and hunting industries which bring in over $90 million and employ almost 2,000 residents. The health of the environment, economy and public safety relies upon these water sources, and therefore it is a resource that must be protected against all pollutants. The Yukon River Inter-Tribal Watershed Council was formed with the goal of raising the quality of the Yukon’s waters to a standard that is safe to drink. Together with residents and government authorities, the Council works to restore and defend the purity of Alaska’s watershed system.

Alaska Department of Environmental Conservation (DEC) NPDES Stormwater Permits

The federal government began the Federal Water Pollution Control Act in 1942 which was amended in 1972 and became the Clean Water Act (CWA). These initiatives sparked laws and guidelines for industries and construction projects that require procedures to mitigate pollutants introduced into the watershed system. Most notably of these requirements is the National Pollutant Discharge Elimination System (NPDES) Permit Program created by the Act. The Permit Program requires industries and construction operators to create plans that will reduce or eliminate the negative impact of its activities.

Alaska Department of Environmental Conservation (DEC) Division of Water has assumed administration of the Permit Program through the Alaska Pollutant Discharge Elimination System (APDES). All construction activities that will affect one or more acres of require a permit. Many projects can be covered under the Construction General Permit for Storm Water Discharges for Large and Small Construction Activities (2021 CGP, AKR100000). To apply for coverage under the General Permit, operators must develop and submit a Stormwater Pollution Prevention Plan (SWPPP) and submit a Notice of Intent to the DEC.

The SWPPP includes an outline of planned construction activities which may cause sedimentation or pollution to water sources. The Plan also lists strategies and devices that will be implemented by the operator in order to contain the contaminants and sediments on the job site to prevent erosion, sedimentation, and pollution. The Alaska DEC publishes the Alaska Storm Water Guide to aid engineers and contractors as they design SWPPP for each project. Included in the Storm Water Guide are commonly used resources and methods that prevent erosion and control sediment in the construction area. Notable and common methods implemented in an effective SWPPP are sediment basins, silt fences, dust control, and stabilized construction exits.

Stabilized Construction Exit and Vehicle Track-Out BMP

Construction site entrances receive a high volume of traffic. The Construction General Permit requires all exit points to established stabilized construction entrance and vehicle track-out BMPs which are designed to remove sediment from construction vehicle tires to minimize sediment that is tracked onto public roadways where it can run into storm drains and cause excessive sedimentation. A stabilized construction exit is usually one of the first practices implemented by an operator prior to other construction activities in order to provide site access to delivery vehicles and heavy machinery onto the construction zone.

Vehicle Track-Out controls include cleaning of the public right-of-way on a regular basis to capture sediment and debris that escapes through the stabilized entrance. Vacuuming, sweeping or shoveling should be conducted on the same day that track-out occurs or on the next business day if the track-out occurs on a non-business day. Cleaning ensures that fugitive debris is captured before it runs into storm sewers and drains or causes roadway hazards.

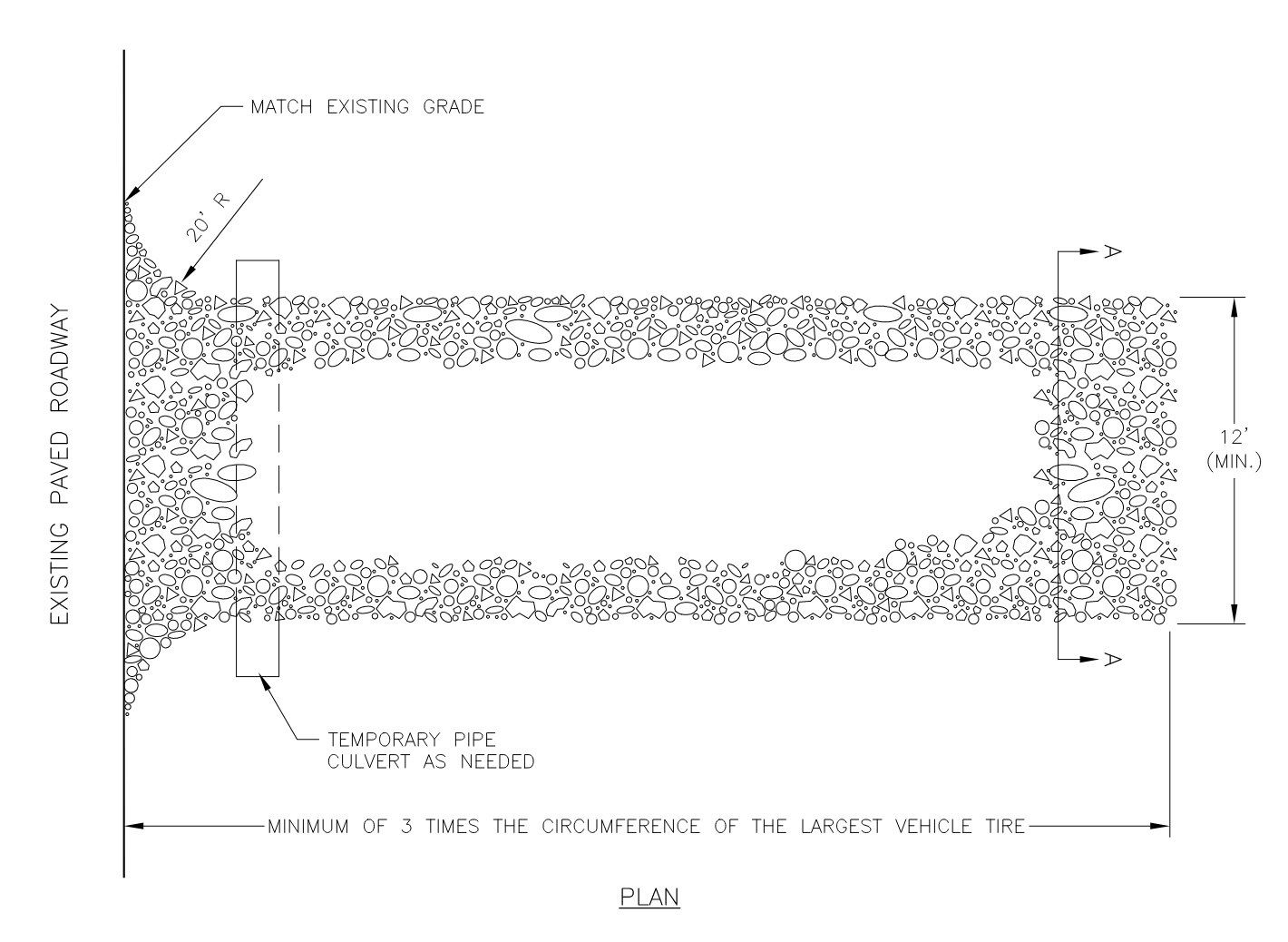

Stabilized Rock Construction Exit BMP

One type of BMP to reduce sediment track-out is a Rock Construction Exit. The Alaska DOT Best Management Practices (BMP) Guide for Erosion & Sediment Control describes common types of BMPs which are used throughout the state and includes an aggregate style Stabilized Construction Entrance. The guide includes design criteria which includes dimensions and considerations. The rock tracking pad consists of a 12’ deep layer of 2-3” stone or quarry spall which is a minimum of 12’ wide. The minimum length of the entrance is designed to provide three complete tire rotations for the largest vehicles which will use the entrance. Before installing the gravel in stabilized vehicle entrance/exit a fiber filter must be installed to separate from the native soil from the tracking pad.

The rock stabilized construction entrance must be observed and maintained throughout the project to keep the entrance in working condition. Over time, vehicles passing over the aggregate will compact the rock and the entrance will become saturated with soil. As the entrance becomes compacted performance decreases and the entrance will need to be repaired. Maintenance of the gravel system is completed by top dressing will additional rock and repairing or replacing the filter fabric if it is torn. During rain events, entrances will require more frequent cleaning.

Additional or alternative BMPs may be required if the aggregate or paved entrance does not sufficiently contain sediment on the job site.

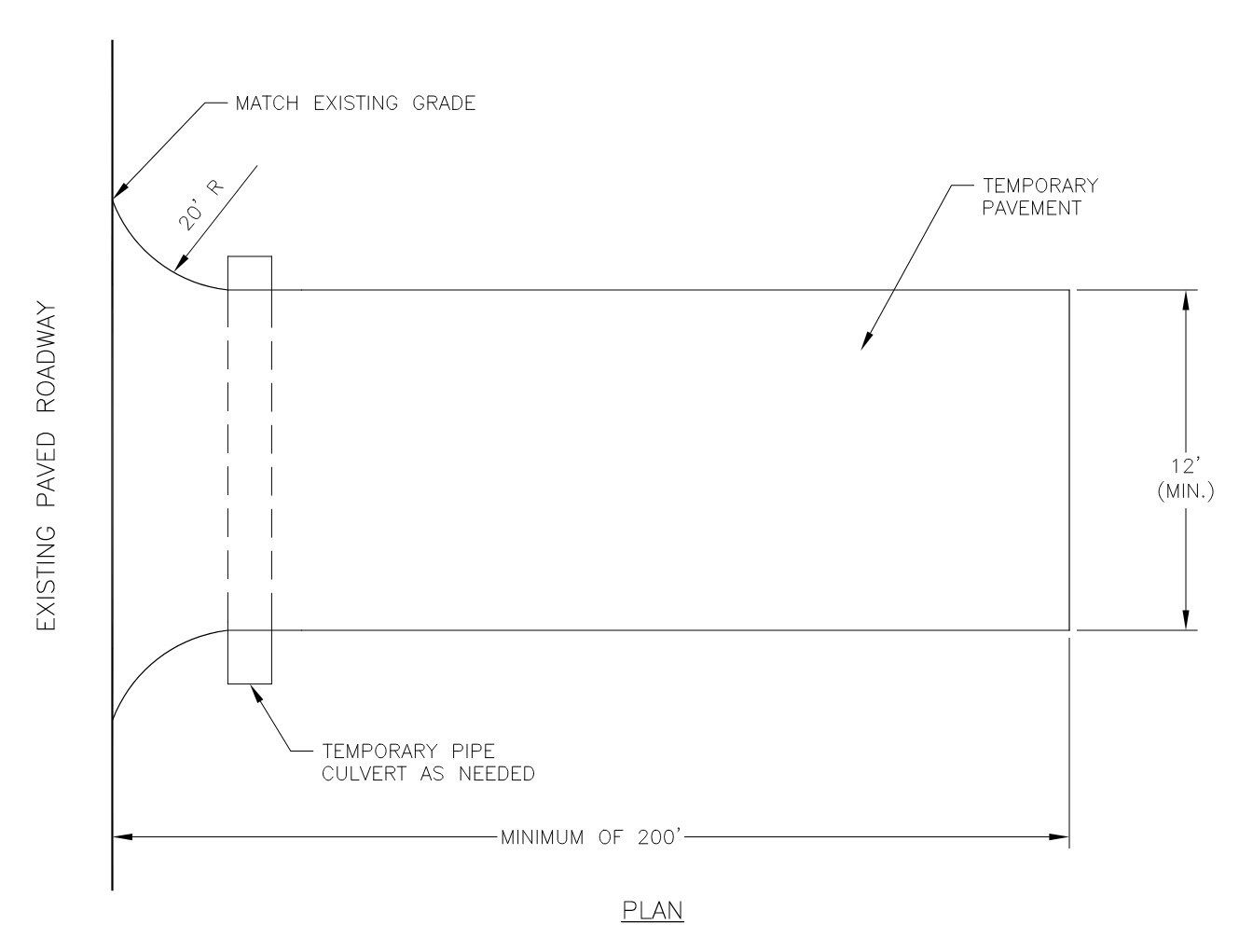

Temporary Paved Construction Exit BMP

In some cases, rock entrances may not be required to contain soil on the site. The Alaska DOT BMP Guide also includes a Temporary Pavement Construction Exit which can be used in some cases in lieu of a Rock Construction Entrance. Temporary Pavement Construction Exits must be installed at a minimum of 200’ in length.

Paved surfaces can be swept to remove sediment and debris that collects on the paved area.

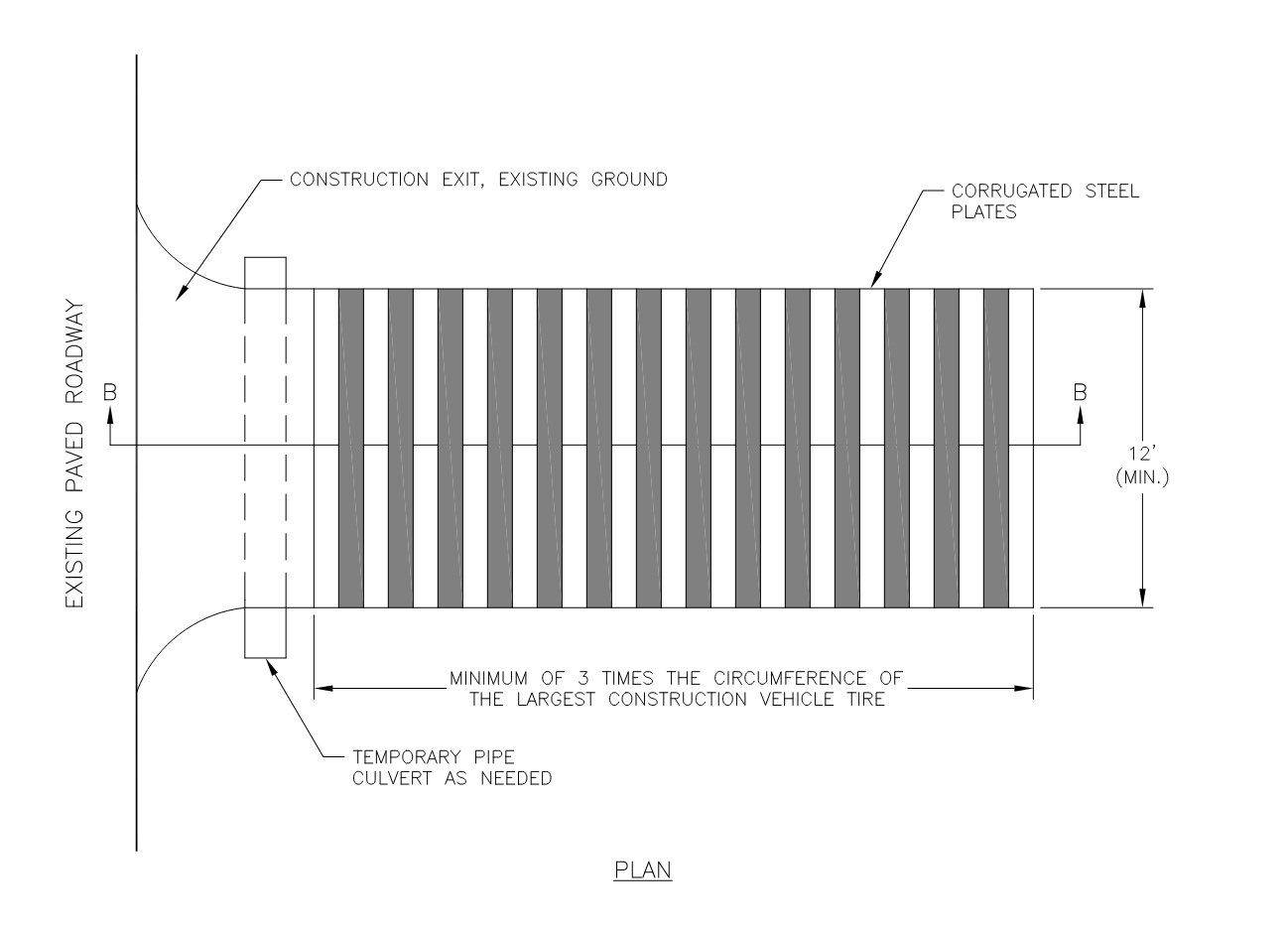

Metal Plate Device BMP

Another technique mentioned in the guide is a Metal Plate Construction Exit which is commonly used in conjunction with Rock Construction Exits. This technique uses a corrugated steel plates, also called shaker plates or rumble plates, which shakes vehicle tires as they exit the site. The shaking motion can help to dislodge additional mud and debris from vehicle tires.

Depending on the type of Metal Plate used, there may be a void below the system which collects sediment, or the spaces between the corrugated ridged will act as a containment area. The system must be cleaned to remove built up sediment over time. It may be necessary to move the plates using equipment to clean the voids below.

Wheel Wash Station BMP

Wheel Wash Stations are an effective technique for cleaning vehicle tires when installed with proper considerations. A wash station uses can be either passive or mechanical. A passive system consists of a pond, of 12” to 14” depth, which is driven through to rinse off of vehicle tires. Passive wash stations should be created with a slight slope, 6” - 10” over the 12’ width, to help sediment collect on the side of the wash station basin. Mechanical wheel wash stations use either manually operated or automated pressure washers to spray mud off of vehicles. Water from the sprayers must be diverted or collected in a sediment basin to prevent run off from entering the roadway.

FODS Trackout Control System

A modern and effective technique for reducing vehicle track-out is the FODS Trackout Control System. This modular system uses a series of 12’ x 7’ HDPE matting which is formed into pyramid shaped structures on the surface. The pyramids deform and flex vehicle tires in multiple directions to dislodge sediment, rocks, and debris which is lodged between tire treads. The most cases system can be installed over existing substrates including dirt, concrete and asphalt.

The FODS Construction Entrance Mats are designed to be reused on multiple projects over the 10+ year expected service life. The mats can be easily relocated which significantly reduces costs on phased projects and over the course of multiple projects. Installation, maintenance, and removal can be completed without the heavy equipment and a standard installation can be completed in under 30 minutes.

The 3” tall pyramids can hold up to 2.5” of sediment as the tires only come into contact with the tips of the pyramids. When maintenance is required, the street sweeper or a skid steer with broom attachment can be used to brush away sediment to restore performance. Manual cleaning can be completed with a FODS Shovel which is designed to fit between rows of pyramids. Contractors can integrate maintenance during regular street sweeping to ensure the entrance is always compliant with permit requirements.

The FODS system outperforms traditional Rock Construction exits and has been shown to reduce street sweeping by 59% in high traffic volume applications. Because the system is highly effective, FODS are commonly specified at 50% of the length of a stone stabilized tracking pad to provide equal performance. In addition, the system cost effective enabling contractors to reduce sedimentation and costs on each project the mats are used.