Harris County Greens Bayou

Contractors Improve Construction Entrances On Flood Risk Reduction Projects

In late August of 2017, Category 4 hurricane Harvey struck the Houston metropolitan area. Counties along the Texas coastline experienced upwards of 40 inches of rain causing unprecedented flooding and caused thirty-three counties to declare a federal disaster. Out of nineteen official river gauges in Harris County, nine recorded all-time high flood stages. The National Guard was deployed to assist with search and rescue and clean up efforts, while FEMA worked to provide temporary shelter for the hundreds of thousands of residents who were affected. After the storm had passed, residents began the multi-year process to rebuild their communities and cities which continues today.

Harris County Funds Excavation Projects

In the aftermath of this event, voters of Harris County approved a $2.5 Billion Bond for Flood Risk Reduction Projects. As of 2019, there were over fifty projects underway which involve heavy excavation to modify and enlarge channels, bayous, banks, and storm water detention basins. The modifications will safely contain and discharge surplus storm water to protect developments and residents in Harris County.

The Harris County Flood Control District (HCFCD) awarded Challenger Service Inc., a full-service excavation and heavy equipment company based in Texas, a $16 million contract to excavate and construct the Lauder Stormwater Detention Basin in the Greens Bayou watershed. This area in North Harris County encompasses densely populated and highly developed sites that have been subject to multiple floods since the late 1970s. When completed, the wet-bottom basin will hold at least 1,200 acre-ft or more than 391 million gallons of surplus storm water which will drain to the bayou.

FODS HDPE Rumble Plates Tested On Excavation Project

Excavation job sites in particular require effective trackout control solutions to prevent mud and sediment from vehicle tires from being deposited onto public roadways. Rock tracking pads, steel rumble plates, and wheel wash systems are traditional methods to reduce job site trackout. During this project, Construction EcoServices, an important source of environmental and storm water protection solutions, provided Challenger Services Inc. with a set of FODS Trackout Control Mats.

As part of a best management practice (BMP) product evaluation, inspectors from HCFCD recorded the performance and benefits of using FODS compared to traditional rock stabilized construction access (SCA). Data was collected regarding durability, maintenance frequency, and street sweeping frequency to determine how well FODS composite rumble plates contained trackout compared to a traditional stone construction entrance. FODS plastic rumble plates or mats consist of an HDPE base with staggered pyramids on the surface. As vehicles drive over the tops of the pyramids, tire lugs open to allow trapped debris to fall to the base of the pyramids. In contract to traditional rumble plates, the mats can be installed over existing soil, and do not require excavation.

During this project, excavation lasted a total of 178 days with a total of 29,745 fully loaded trucks leaving the site. During the first 56 days of excavation, a traditional TxDOT Construction rock stabilized construction entrance while FODS composite mat system was used during the remaining 122 days to enable a side by side comparison.

FODS Trackout Control Mat Evaluation Results

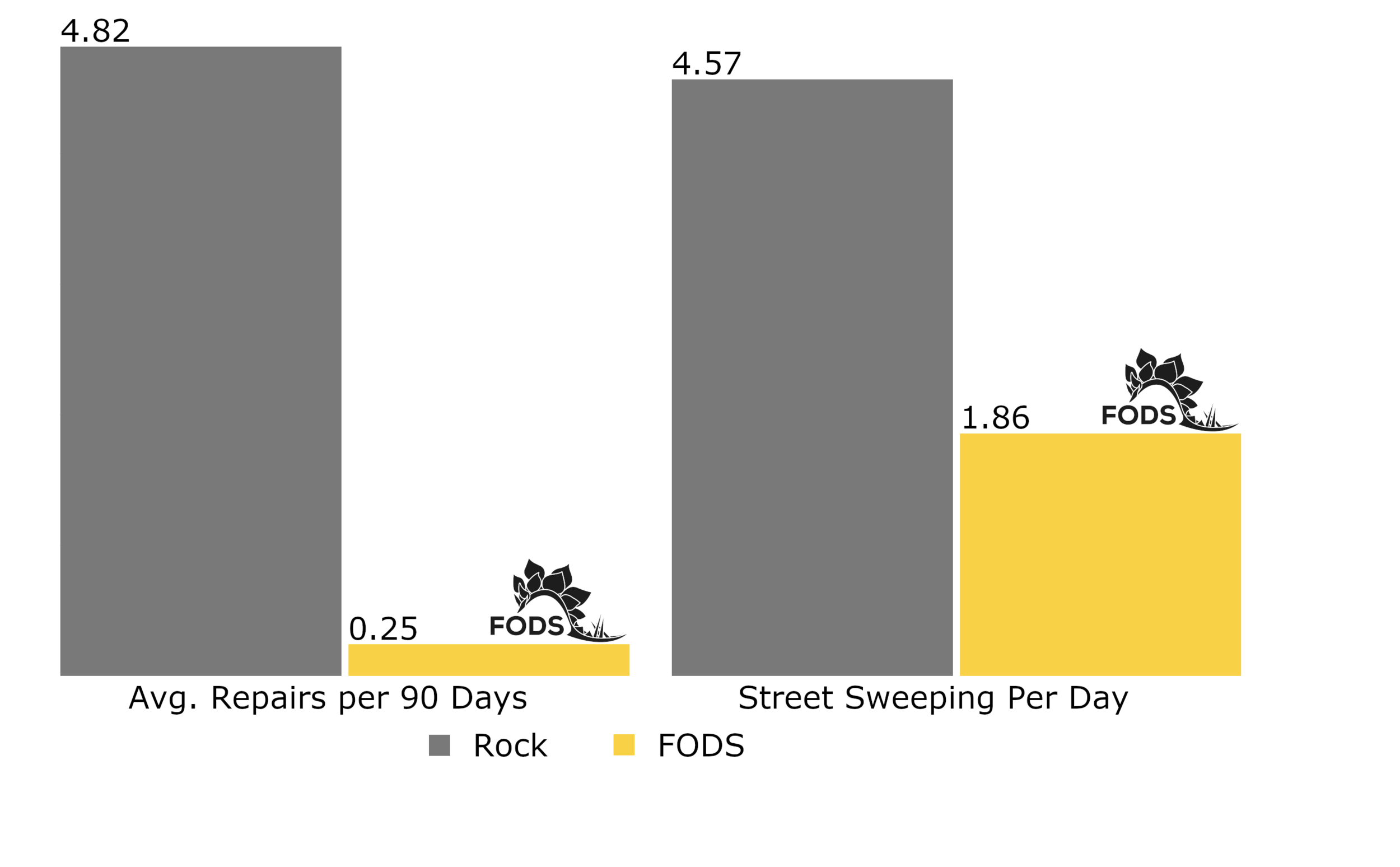

HCFCD analyzed the report results which revealed key differences between rock systems and FODS trackout mats. Compared to refreshing construction entrances with additional rock, FODS Trackout Control Mats can be easily cleaned off to restore functionality. Over the first 56 days of use, the traditional stone construction entrance required 9 additional top dressings and 39 rock mixings to stay in compliance. During the project, FODS manufactured construction exit provided access to 20,354 fully loaded 80,000lbs trucks over the course of 122 days. Besides quick and simple cleanings, only a single repair was needed which involved the re-hammering down on the anchoring stakes. The use of FODS improved compliance and reduced liability by preventing dirt tracked onto the roadway. In total, the FODS were used to clean the tires of over twice as many trucks as the traditional rock construction entrance.

Rock VS. Reusable Construction Entrance System

While rock is removed and discarded at the end of a project, FODS reusable trackout control mats are simply transported to the next site to continue to provide effective trackout control. Engineered for extreme durability and environmental sustainability, FODS have an estimated lifespan of over 10 years. FODS can be completely recycled at the end of their service life enabling lower impact on the environment. Excavation contractors can reuse FODS stabilized entrances to operate at a lower cost and decreased liability.

The report concluded that FODS increased job site compliance and reduced roadway cleaning:

HCFCD analyzed the data and determined that FODS provide equal or greater performance than SCA. Use of FODS decreased roadway cleaning by 59% when compared to SCA. FODS required 89% less repair than SCA. FODS required more frequent cleaning than SCA, however, the FODS cleaning effort was less time consuming and resulted in cleaner roadway. Use of FODS improved compliance with the Contstruction General Permit and reduced liability by preventing dirt tracked onto Lauder Rd.

The decreased amount of FODS repairs resulted in less time lost to the contractor and more time excavating. This particular instance would have reached 100% decrease as the single repair needed resulted from faulty installation of a tie down.

It is recommended that special specification created for FODS for use on HCFCD projects as an alternative to SCA.

Report Data

| Total Trucks | Avg. Trucks per Day | Total Days | Repairs/Refresh Required | Avg. Repair/Refresh per 30 Days | Total Street Sweeping | Street Sweeping per Day | |

|---|---|---|---|---|---|---|---|

| Rock | 9391 | 168 | 56 | 9 | 4.82 | 254 | 4.57 |

| FODS | 20354 | 167 | 122 | 1* | 0.25* | 227 | 1.86 |

Percent Difference Compared to Rock

| Repair Reduction | Street Sweeping Reduction | |

|---|---|---|

| FODS | 94.8% | 59% |

*Repair = Reanchoring of FODS TCS.

Future Uses & Feedback

This project provided the valuable data needed to step towards the use of FODS as an alternative to traditional stabilized construction access solutions. As Harris County continues to implement the remainder of the flood risk reduction efforts, FODS will provide value to contractors by offering effective, sustainable and reusable trackout control options at a lower cost per job.

The contractor commends about using FODS in various weather conditions:

“With our experience with the system we observed that it cut the amount of street sweeping we had to perform by half on rainy and dry days.”

“All in all, Challenger had a very positive experience using the FODS and would definitely recommend them to other contractors.”

– Zach Parker, Challenger Texas

The projects currently underway are focused on the areas with the greatest risk of flooding. The full scope of the planned project spans the next 10-15 years as the HCFCD works to improve flood resilience across the county. The scale of work that has begun demonstrates the opportunity for novel and innovative solutions to improve the ability for excavation contractors to better serve the needs of their communities. FODS welcomes the opportunity to play a role in the rebuilding of American cities across the country.

“Harris County residents have put their trust in the Flood Control District and we plan to work extremely hard and efficiently to turn the financial resources made available as a result of this election into the reality of reduced flooding risks across Harris County,”

- Russell Poppe, Executive Director for the Harris County Flood Control District