Palisades Tunnel Project — Hudson County, NJ

The Palisades Tunnel Project in Hudson County, New Jersey, is one of the largest underground construction efforts currently underway in the Northeast. As the first major tunneling contract of the Gateway Program’s Hudson Tunnel Project, it lays the groundwork for a new dual-rail connection between New Jersey and New York City.

The work is being handled by the Schiavone Dragados Lane Joint Venture, a partnership between The Lane Construction Corporation, Schiavone Construction Company, and Dragados USA. Together, these firms employ over 7,500 civil and structural engineers worldwide, bringing deep expertise in tunneling, bridge construction, and the development of complex infrastructure. The $466 million contract encompasses approximately one mile of twin tunnels beneath the Hudson Palisades, along with multiple shafts, cross passages, and related support structures.

For the communities surrounding the western portal near Tonnelle Avenue in North Bergen, the project represents both an engineering milestone and an environmental test. The Palisades Tunnel will form the starting section of a new Hudson River rail crossing meant to boost capacity and reliability along the Northeast Corridor. The current North River Tunnels, which date back to 1910, carry hundreds of trains daily and have become a weak point in the region’s transportation network. Building a new, modern tunnel system enables the Gateway Development Commission and its partners to enhance long-term reliability, aligning with national sustainability and infrastructure goals.

Shaped by the Palisades

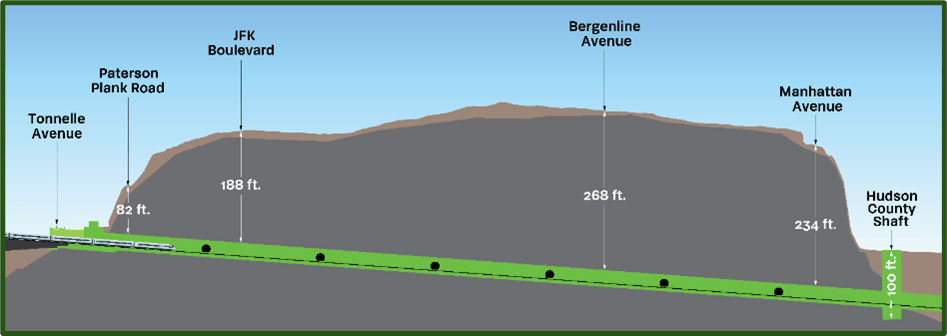

The tunnel runs east from North Bergen toward Weehawken, cutting through the diabase rock that forms the Hudson Palisades. The cliffs are a defining part of the landscape, and they shape how the work gets done. The rock is strong and stable, which helps control movement around the excavation, but it’s also extremely dense. Crews rely on specialized equipment and careful sequencing to get through it without slowing the broader schedule.

This stretch of the Hudson waterfront has supported rail lines, maintenance yards, and utility corridors for more than a century. Rebuilding and expanding that infrastructure in the middle of a tight urban area takes coordination at nearly every level. Every truck leaving the site, each access road, and every shaft operation is subject to strict review by the New Jersey Department of Environmental Protection and the Hudson County Soil Conservation District. With so many people and businesses close by, even routine tasks require planning.

Managing sediment and compliance

Urban tunneling projects present unique sediment control challenges. Unlike greenfield construction, sites in Hudson County are tightly surrounded by public roads, businesses, and residential areas. There is a large risk of track-out daily because of the continuous movement of heavy equipment in and out of the Tonelle Avenue staging yard. The project team developed a sediment control plan under the New Jersey Pollution Discharge Elimination System, integrating stabilized access points, drainage collection zones, and monitoring protocols to prevent sediment and debris from reaching nearby streets.

Being so close to the Hudson River raises the bar even further. Runoff from the site has to be collected, routed into approved containment basins, and treated before discharge. And with New Jersey weather shifting between rain, freeze–thaw cycles, and summer heat, the team needed access points that would stay stable no matter the season. While traditional rock pads were initially considered for the site’s entrances, engineers found that manufactured trackout control systems offered better performance given the tight space, heavy truck traffic, and constantly changing haul routes.

Manufactured trackout control

To help meet sediment control and stormwater compliance goals, the Schiavone Dragados Lane team installed FODS Trackout Control Mats at key construction exits. Made in the U.S. from high-density polyethylene, these durable, reusable mats are designed to keep mud and debris from leaving the site.

Each 12-by-7-foot mat features a tapered pyramid pattern that creates a washboard effect as trucks and equipment drive across it. The raised pyramids flex the tires, shaking loose mud, dirt, and debris from the treads and undercarriage. This rapid, mechanical cleaning helps prevent sediment from tracking onto public roads while standing up to continuous heavy-vehicle use on busy, high-traffic sites.

Installation followed NJDEP guidance for manufactured devices, including placement on stable subgrades and sufficient device length to ensure full tire contact. At the Tonnelle Avenue portal, mats were positioned at key outbound lanes used by haul trucks and delivery vehicles. Additional mats were added at secondary exits near equipment storage and laydown areas. The modular design allowed the system to be moved and reused as the project advanced.

Switching to a manufactured system cut down the number of rock deliveries, reduced waste generated by traditional gravel pads, and kept the site cleaner over time. The mats stayed consistent through weather swings and carried the daily load of truck traffic without needing to be replaced.

Clean roads and safe access

Maintaining clean roadways around a project of this scale is critical for both public safety and community relations. The project area borders several high-traffic corridors in North Bergen, including Tonnelle Avenue and Paterson Plank Road, where sediment or debris could create hazards for local vehicles and motorists. Through a combination of stabilized work surfaces and manufactured trackout control, the construction team helped reduce visible mud and dust on surrounding streets and maintain safe conditions for vehicles entering and leaving the site.

Supporting regional sustainability goals

The Palisades Tunnel Project fits into the Gateway Program’s broader sustainability efforts, which focus on reducing waste and improving environmental performance on major infrastructure projects. By choosing reusable trackout control mats instead of disposable rock entrances, the team lowered material use and avoided the constant cycle of ordering, replacing, and removing aggregate. Switching to a manufactured system also cut down the number of trucks coming in with fresh rock and hauling old material out. That alone reduced noise, traffic, and the constant disruption that usually comes with maintaining gravel entrances.

The mats also get reused as the job moves, which helped stretch the budget and avoided the repeated emissions tied to hauling rock back and forth. And by keeping sediment out of the storm system, the team helped protect the Hudson River and stayed in line with the state’s goals for cleaner waterways and better construction practices in busy urban areas.

Looking ahead

As the first tunneling contract to move forward under the Gateway Program, the Palisades Tunnel Project represents both an engineering and environmental milestone. By combining advanced tunneling technology with sustainable site management, the project demonstrates how major infrastructure investments can achieve high performance standards while maintaining compliance with environmental regulations.

For the Schiavone Dragados Lane Joint Venture, the experience highlights the importance of integrating sediment control planning into early design and mobilization. The use of reusable trackout control systems has proven to be both practical and environmentally responsible, helping the team maintain operational efficiency while supporting long-term sustainability objectives.

When completed, the Palisades Tunnel will form a key link in the new Hudson Tunnel system, improving rail reliability and capacity between New Jersey and New York while setting a model for sustainable construction practices in one of the most complex urban environments in the country.