The Hidden Engine of Amusement Parks

Amusement parks are symbols of joy, excitement, and family fun. Guests typically associate them with bright lights, thrilling rides, and unforgettable memories. Yet beneath this public-facing magic lies a complex operational ecosystem—one that rivals the logistical sophistication of manufacturing plants and major heavy civil construction projects. In 2025, the U.S. amusement park industry generated more than $35 billion annually, a scale that underscores both the commercial importance and operational demands of these destinations.

To keep the rides running and the environment pristine, parks must constantly engage in construction, repair, and logistical coordination. This means that behind every roller coaster launch and firework finale is a fleet of forklifts, cranes, trucks, and maintenance crews working tirelessly to ensure that infrastructure is not only functional but also safe and efficient.

One iconic Florida amusement park, known worldwide for its immersive guest experience, recently faced a new and demanding construction challenge. A solution they selected to be part of the project, FODS Ground Protection Mats, proved to be a pivotal asset in maintaining operational efficiency while protecting the park’s critical back-of-house infrastructure.

Logistics Under Pressure

The project centered on a large-scale concrete repair and replacement program, requiring the delivery, staging, and movement of over 3,000 concrete masonry units (CNUs). These materials had to be stored in a dedicated laydown yard, with constant movement of heavy equipment transporting tools, blocks and other materials to active work zones.

The equipment roster included industrial forklifts and front-end loaders, both of which exert tremendous pressure on surfaces. Over time, repeated passes create ruts, destabilize soil, and cause unsafe working conditions for operators. These surface failures slow down progress and increase project costs through required remediation.

The Risks of Traditional Methods

Historically, amusement parks and construction contractors have relied on traditional materials like plywood sheets and aggregate rock to stabilize temporary work zones. While these methods offer basic functionality, they fall short in demanding, heavy-duty environments. Plywood quickly deteriorates under the concentrated weight of forklifts and heavy equipment, often splintering, bowing, and creating safety hazards for crews. Aggregate rock, while more durable, provides inconsistent stability and requires constant grading, replenishment, and costly removal once projects conclude. Without reliable ground protection, exposed soil becomes compacted and rutted, leading to compliance issues, extended project timelines, and increased maintenance costs.

For this Florida project, Edwards Concrete, a master Bomanite installer and highly regarded contractor in the Orlando and Central Florida region, recognized that conventional methods were inefficient, unsustainable, and incompatible with the amusement park’s high safety and environmental standards.

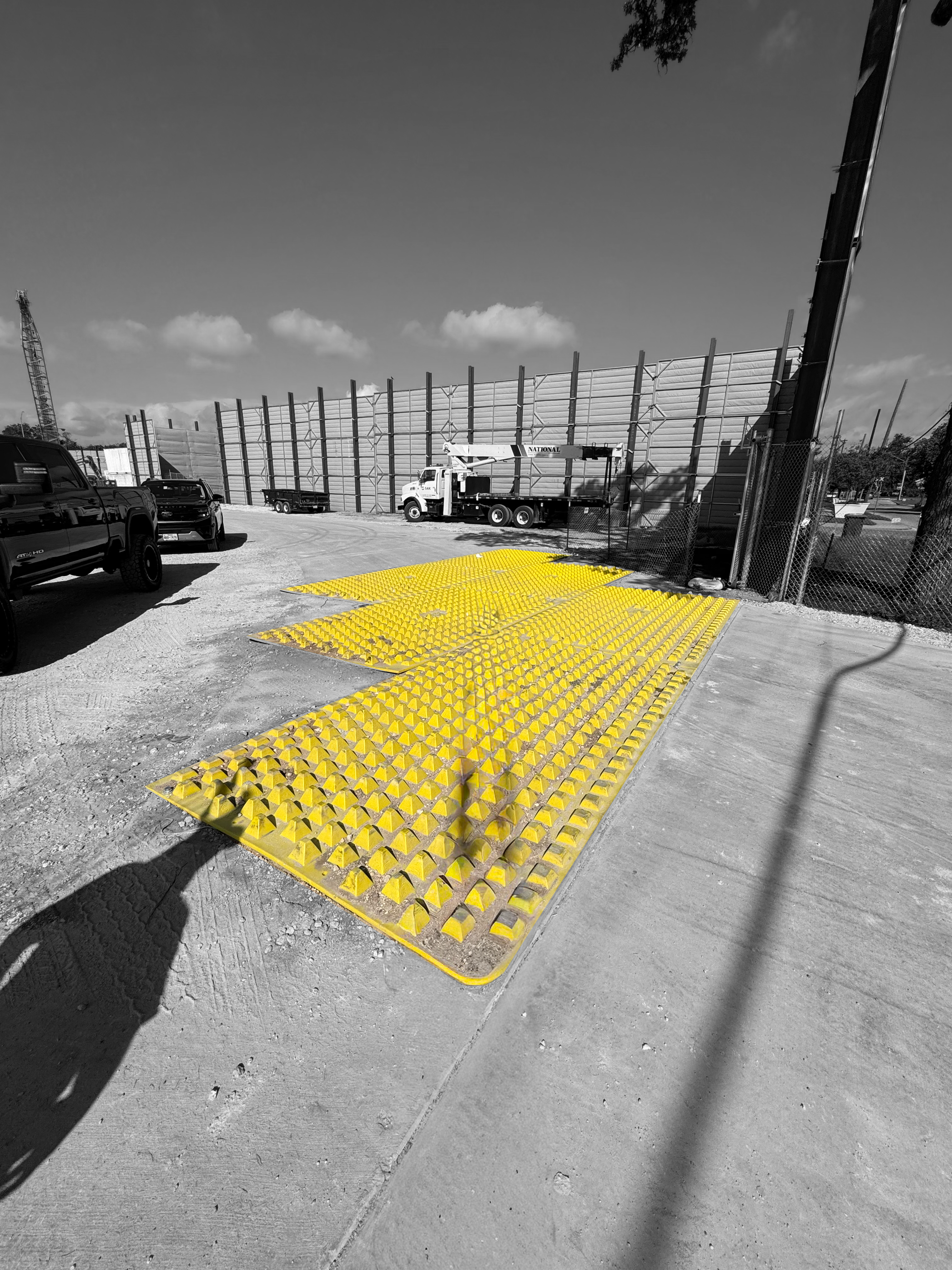

Deploying FODS Ground Protection Mats

After evaluating alternatives, the project team selected FODS 4’x8’ Ground Protection Mats, an engineered high-density polyethylene (HDPE) panels with an integrated anti-slip traction profile, designed to provide heavy-duty, reusable ground reinforcement.

Key advantages included:

Key advantages of the system included superior load distribution, traction, durability, and sustainability. The mats effectively dispersed concentrated forklift weight across a larger surface area, preventing soil rutting and ensuring smooth, stable navigation throughout the work zone. Their engineered anti-slip surface allowed both operators and equipment to maintain reliable traction even in wet or uneven conditions, significantly enhancing on-site safety.

Installation was fast and efficient, with crews able to deploy and reposition mats quickly to create forklift lanes and staging areas as project priorities shifted. In contrast to plywood, which deteriorates within days, or thin plastic alternatives with limited lifespans, FODS Ground Protection Mats are built for years of repeated use in demanding environments. Additionally, their reusable and recyclable design supported the park’s commitment to environmental responsibility by reducing material waste and promoting long-term sustainability.

From Setup to Daily Operations

The mats were strategically placed to form defined forklift lanes and staging zones in the high-traffic laydown yard. Using FODS interlocking connecting hardware, the design prevented movement under repeated turning movements and ensured stable alignment.

The creation of this working platform provided operators smoother driving conditions and safer equipment handling. One project lead, Jordan, noted that the mats “stabilized the work zone from the first day and eliminated concerns about ground degradation.”

In a high-intensity environment where forklifts moved thousands of pounds of material multiple times a day, this stability directly contributed to meeting schedule deadlines.

Performance Outcomes

The results of the deployment were both measurable and decisive. Throughout the project, there were zero safety incidents or ground-related interruptions, demonstrating the system’s reliability under continuous heavy equipment use. The underlying substrate remained intact and undisturbed, eliminating any need for costly post-project soil remediation or landscape repair.

Operators maintained consistent productivity, with forklifts and transport vehicles moving efficiently across stable surfaces. More than 3,000 CNUs were staged, transported, and placed without a single delay caused by ground failure. This reliable performance translated directly into measurable time and cost savings, enabling crews to stay focused on completing critical infrastructure upgrades instead of pausing work to repair ruts, replace plywood, or regrade aggregate.

Protecting Brand Reputation

For one of America’s best-known amusement parks, brand value extends well beyond the attractions themselves. Operational excellence must be invisible to guests—any disruptions in cleanliness, safety, or accessibility risk undermining the guest experience.

By using FODS Ground Protection Mats, the park ensured that critical construction logistics unfolded seamlessly, away from the public eye. While no guest ever saw the mats, they played a pivotal role in maintaining the operational integrity that supports the park’s reputation for excellence.

Why This Case Matters Beyond Amusement Parks

Although this project took place within a world-class entertainment environment, its lessons extend far beyond the amusement sector. Industries that rely on efficient logistics and surface stability face similar challenges, from industrial yards and construction sites to municipal infrastructure and large-scale energy projects. In these contexts, advanced ground protection systems play a critical role in maintaining operational continuity.

In industrial yards, they prevent pavement damage and soil degradation caused by repeated forklift or truck movement. On construction sites, they stabilize access roads, staging areas, laydown yards, and pedestrian walkways. Municipal projects benefit from their ability to support temporary detours or material staging without harming existing surfaces, while energy developments depend on them for reliable access to turbines, transformers, and heavy equipment. This case ultimately demonstrates that when projects demand efficiency, safety, and cost control, reusable ground protection offers superior long-term value and performance.

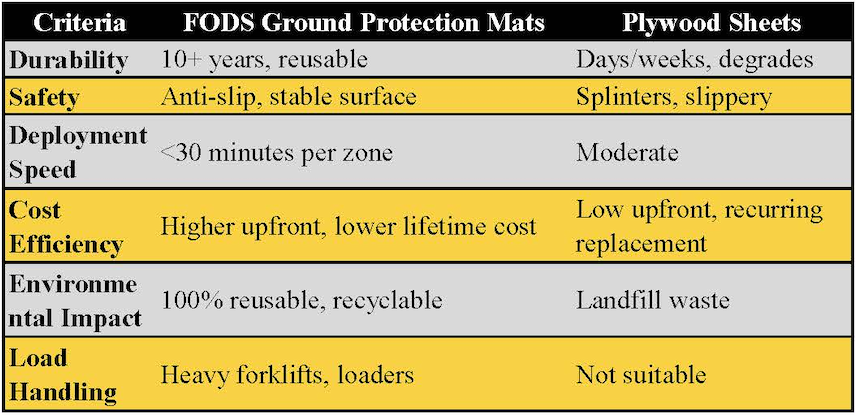

FODS vs. Traditional Methods

This side-by-side evaluation reinforces why Edwards Concrete and the amusement park chose FODS: not just as a temporary fix, but as a strategic investment in operational reliability.

Broader Industry Trends

The adoption of advanced matting systems such as FODS 4’ x 8’ Ground Protection Mats reflects a wider shift across the construction and logistics sectors toward sustainability, cost efficiency, and risk reduction. Contractors and site managers are increasingly moving away from disposable materials like plywood and aggregate rock in favor of reusable, engineered solutions that deliver predictable performance and long-term value. With growing regulatory attention on stormwater compliance, dust control, and site safety, durable ground protection systems are becoming an essential component of modern project planning rather than an afterthought.

Lessons Learned

This project highlighted the importance of integrating ground protection strategies early in the planning phase to ensure smooth and uninterrupted operations. It also reinforced the need to evaluate materials based on lifecycle cost rather than initial expense; while plywood or rock may appear more affordable upfront, their limited durability and maintenance demands drive up long-term costs. Prioritizing surface stability and operator safety proved crucial to maintaining efficiency, particularly in a guest-facing environment where back-of-house disruptions can quickly impact overall reputation and visitor experience.

Conclusion

Every element of the project contributed to maintaining the park’s standard of operational excellence and guest satisfaction. While the public never saw the logistics behind the scenes, the stability of the laydown yard played a critical role in the successful completion of the concrete repair effort. By selecting FODS 4’ x 8’ Ground Protection Mats, Edwards Concrete and the park achieved efficient movement of over 3,000 CNUs, sustained consistent equipment performance, avoided soil remediation costs, and maintained a perfect safety record. Together, these results ensured that the project met its technical objectives while preserving the smooth, reliable operations that define the park’s reputation. The outcome was clear: the magic continued because FODS kept the logistics grounded.