SAK Tunnel Boring – Austin, TX

Austin’s Flooding and Growth

In the heart of Texas, the City of Austin continues to be one of the fastest growing cities in the U.S. With its thriving tech sector, expanding universities, and vibrant downtown area, the region has become one of the fastest-growing metropolitan areas in the United States. That growth, however, has created a strain on the city’s transportation network. Unable to keep up with the growing population, a change is needed to support transportation and create flood control infrastructure.

Interstate 35 is the backbone of Austin’s transportation network. Cutting straight through the heart of the city, it links downtown Austin to local streets and major routes spanning Dallas, San Antonio, and even Mexico. Every day, more than 200,000 vehicles travel along this corridor, making it one of the busiest highways in Texas and a key driver of the state’s economy. Still, I-35 faces ongoing challenges, from heavy congestion to frequent maintenance needs and safety concerns.

In the center of these challenges is the recurring threat of flooding. Downtown Austin lies within a complex topography of steep watersheds that feed into the Colorado River. Sudden, intense rainfall often overwhelms the drainage systems that were originally designed for a much smaller city. The systems in place were not built to withstand how much the population has grown in Austin. In low-lying sections of I-35, even short storms can create dangerous ponding and temporary closures. Climate change and continued urbanization have only intensified these risks.

For decades, Austin addressed flooding with incremental fixes, culvert expansions, storm drain extensions, and other localized improvements. While these measures provided temporary relief, they never resolved the core limitations of the city’s aging stormwater network. By the early 2020s, it became evident that any full reconstruction of I-35 through downtown would require a modern, large-scale underground drainage system.

TxDOT’s Capital Express Central program provided that opportunity. Designed to do more than expand capacity, the program aims to rebuild I-35 into a resilient, multimodal corridor capable of supporting Austin’s growth for decades. Achieving that vision required a robust foundation, one that could manage extreme rainfall events while sustaining major surface improvements. The SAK Tunnel Boring Project emerged as that foundation, setting the stage for one of the most significant drainage infrastructure undertakings in the region’s history.

Building the Foundation for I-35

The SAK Tunnel Project establishes a deep-bore stormwater system running more than six miles beneath downtown Austin. This system will capture runoff from the city’s densest areas and convey it safely to the Colorado River. At its core are two massive tunnels and a new pump station near US-183 designed to move approximately 101,000 gallons of water per minute.

The tunnels form the first phase of the Capital Express Central effort. Without them, lowering and expanding the highway would expose new lanes to constant flood risk. By addressing drainage first, TxDOT ensures that the rest of the project can proceed without interruption and that the city’s primary transportation corridor remains protected against future storm events.

Beyond preventing flooding, the tunnel system is a catalyst for Austin’s continued growth. By securing the city’s most critical infrastructure against extreme weather, it allows developers, businesses, and residents to invest confidently in the urban core. The project also embodies TxDOT’s broader goal of integrating resilience and sustainability into every stage of planning and construction.

From a construction perspective, building below the city first creates a cleaner, more controlled foundation for future highway work. It eliminates the need for multiple surface-level drainage upgrades and minimizes long-term maintenance costs. Once operational, the tunnels and pump station will serve as the backbone of Austin’s modernized transportation network, silently supporting everything built above.

Designing the Tunnel System

The SAK Tunnel Project was developed through collaboration among some of the nation’s leading civil and geotechnical engineering firms. BGE Inc. and Schnabel Engineering led the design and modeling, while SAK Construction and J.F. Shea Construction deliver the tunneling through a joint venture agreement. Each partner brings specialized expertise in underground works, hydraulic design, and risk management.

Early design concepts included multiple small tunnels following different alignments. Engineers later determined that a consolidated dual-tunnel configuration would deliver greater hydraulic efficiency and reduce construction risk. The final design includes two primary bores, each with a finished inside diameter of 22 feet, excavated primarily through limestone and dolomite.

Tunnel A runs roughly 3.5 miles beneath the I-35 corridor, capturing runoff through a series of vertical shafts distributed along the route. Tunnel B stretches just over 3 miles beneath Cesar Chavez Street and provides redundancy for parallel flow conveyance. Together, the tunnels will handle stormwater volumes far beyond the capacity of Austin’s current drainage network.

At the southern end of the system, the Capital Express Central Drainage Pump Station anchors the network near the Colorado River. The station includes multiple high-capacity pumps, advanced electrical systems, and redundant controls. Its staging capability allows operators to modulate flow depending on storm intensity, ensuring continuous operation even when the river rises. The pump station also includes provisions for future upgrades, allowing TxDOT to expand capacity as Austin grows.

Beneath the surface, the tunnels and shafts form a self-contained hydraulic network designed to intercept stormwater directly from the roadway and surrounding neighborhoods. Each shaft is built as both an inlet and a long-term maintenance point, simplifying future inspection and repair.

The technical complexity of this network required extensive modeling. Hydraulic simulations were conducted to predict stormwater behavior during 10-, 50-, and 100-year rain events. These analyses guided the alignment, tunnel diameters, and shaft spacing. The system’s configuration minimizes surface disruption while maximizing conveyance efficiency, ensuring that water is collected quickly and transported away from critical roadways.

Engineering and Urban Constraints

Constructing two massive tunnels beneath downtown Austin requires meticulous planning and coordination. The alignment passes under active streets, utilities, and commercial districts, leaving very little room for error. Each shaft location had to be selected with care to avoid interfering with existing infrastructure and to maintain access for construction equipment and public safety.

SAK Construction and J.F. Shea have decades of combined experience in tunneling and deep-bore excavation. Their joint venture brings the technical expertise and logistical management required to execute complex projects in dense urban environments. Working closely with TxDOT and the City of Austin, they developed detailed staging plans that minimize disruption to residents and businesses.

Traffic management has been a central challenge. I-35 is one of the most congested highways in the state, and maintaining mobility during construction was essential. The project team coordinated lane closures with TxDOT’s mobility office to ensure work occurred primarily during off-peak hours. Detour plans, temporary barriers, and continuous communication with the public have helped keep Austin moving even as excavation progresses below.

Geotechnical conditions also play a significant role in the project’s execution. Austin’s subsurface consists of alternating layers of limestone, dolomite, and soft sediments near the river. These transitions create variable ground conditions that must be managed carefully to avoid settlement or collapse. Shafts are stabilized with temporary steel liners until permanent concrete supports are installed. Continuous monitoring ensures the integrity of both the excavation and the surrounding infrastructure.

Tunneling operations rely on precision boring equipment designed for hard rock excavation. Specialized tunnel boring machines (TBMs) are being used to advance through the limestone at controlled rates, maintaining alignment and minimizing vibration at the surface. The TBMs are equipped with instrumentation that allows engineers to track real-time progress, pressure, and ground conditions.

Construction logistics in downtown Austin require careful sequencing. Limited staging space means that materials, equipment, and spoil removal must be coordinated with precision. Excavated material is transported along planned haul routes to minimize disruption. Work crews operate within tight time windows, maintaining a balance between production efficiency and community impact.

Noise and vibration control have also been key considerations. The project team implemented a monitoring program to measure and limit potential disturbances for nearby residents and businesses. By combining sound barriers, schedule management, and low-impact excavation techniques, the contractors have maintained compliance with local ordinances while keeping operations efficient.

Environmental Compliance and Sediment Control

Environmental responsibility is an integral part of the SAK Tunnel Project. Because construction occurs within Austin’s urban core and near the Colorado River, stormwater management and sediment control are subject to strict oversight. TxDOT and its contractors operate under the Texas Pollutant Discharge Elimination System (TPDES), which sets standards for erosion control and stormwater discharge during construction.

Each staging and shaft area is managed under a Stormwater Pollution Prevention Plan, or SWPPP, developed specifically for the project. The plans identify potential sources of runoff, designate containment zones, and define best management practices for sediment control.

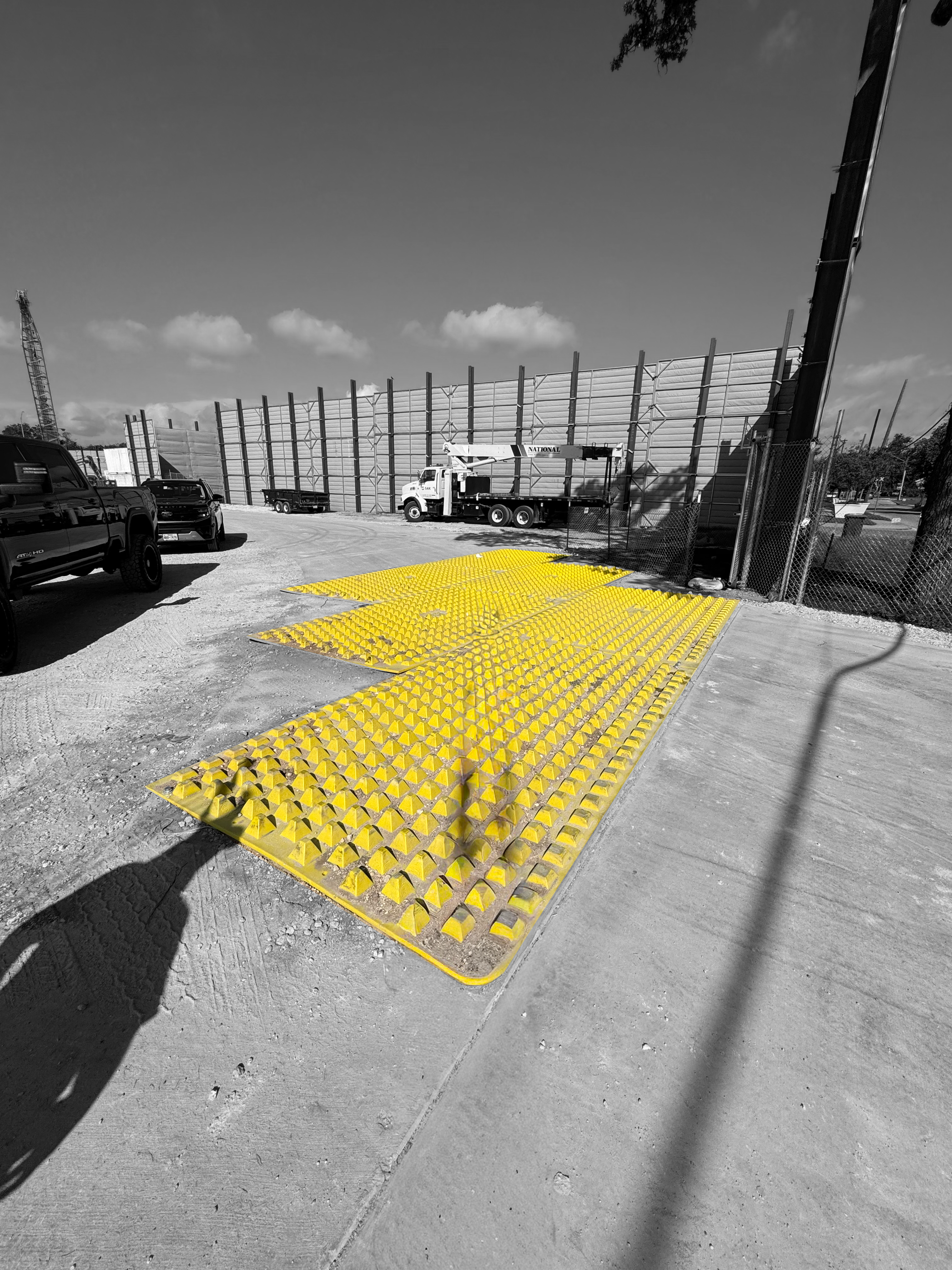

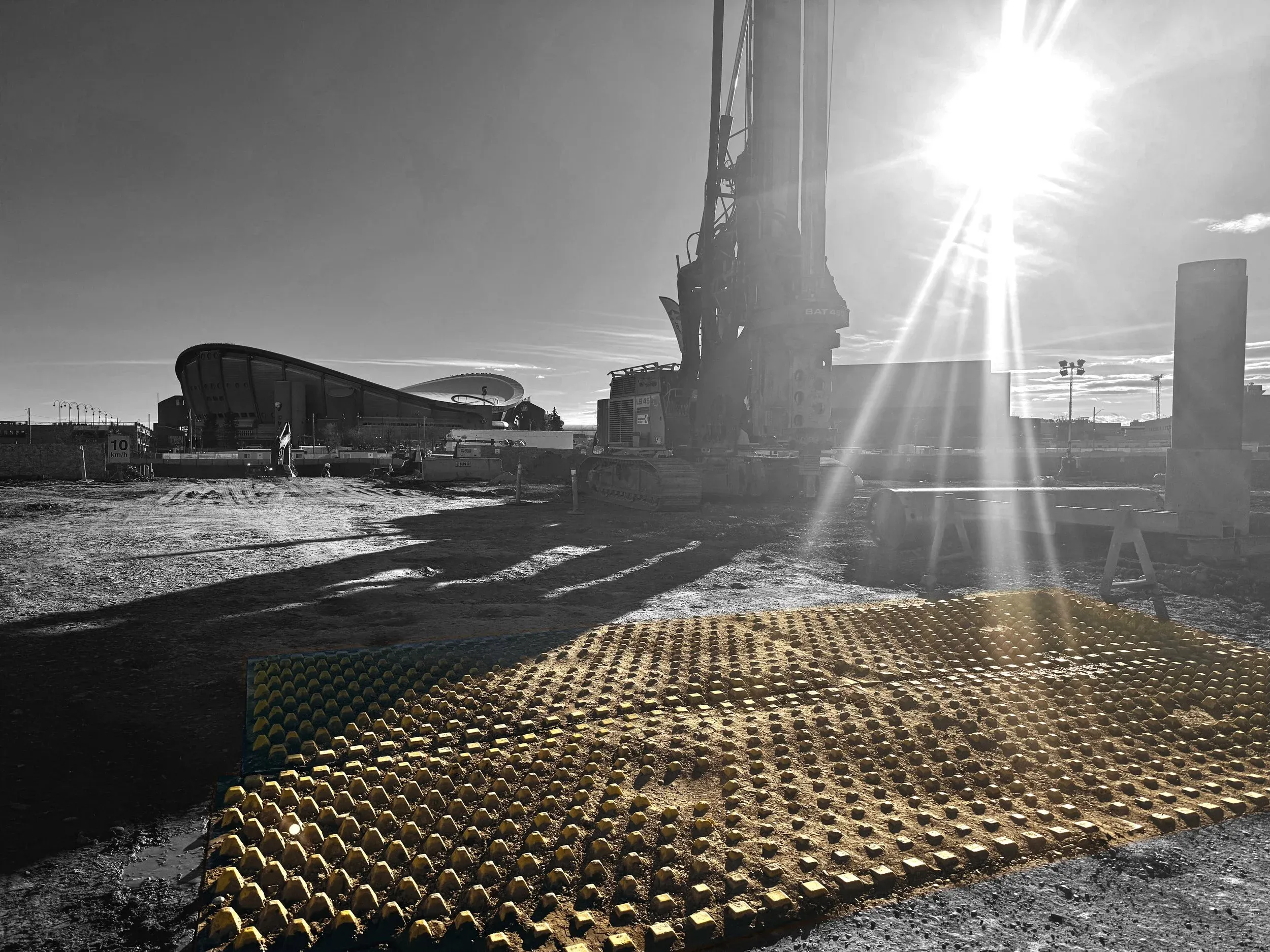

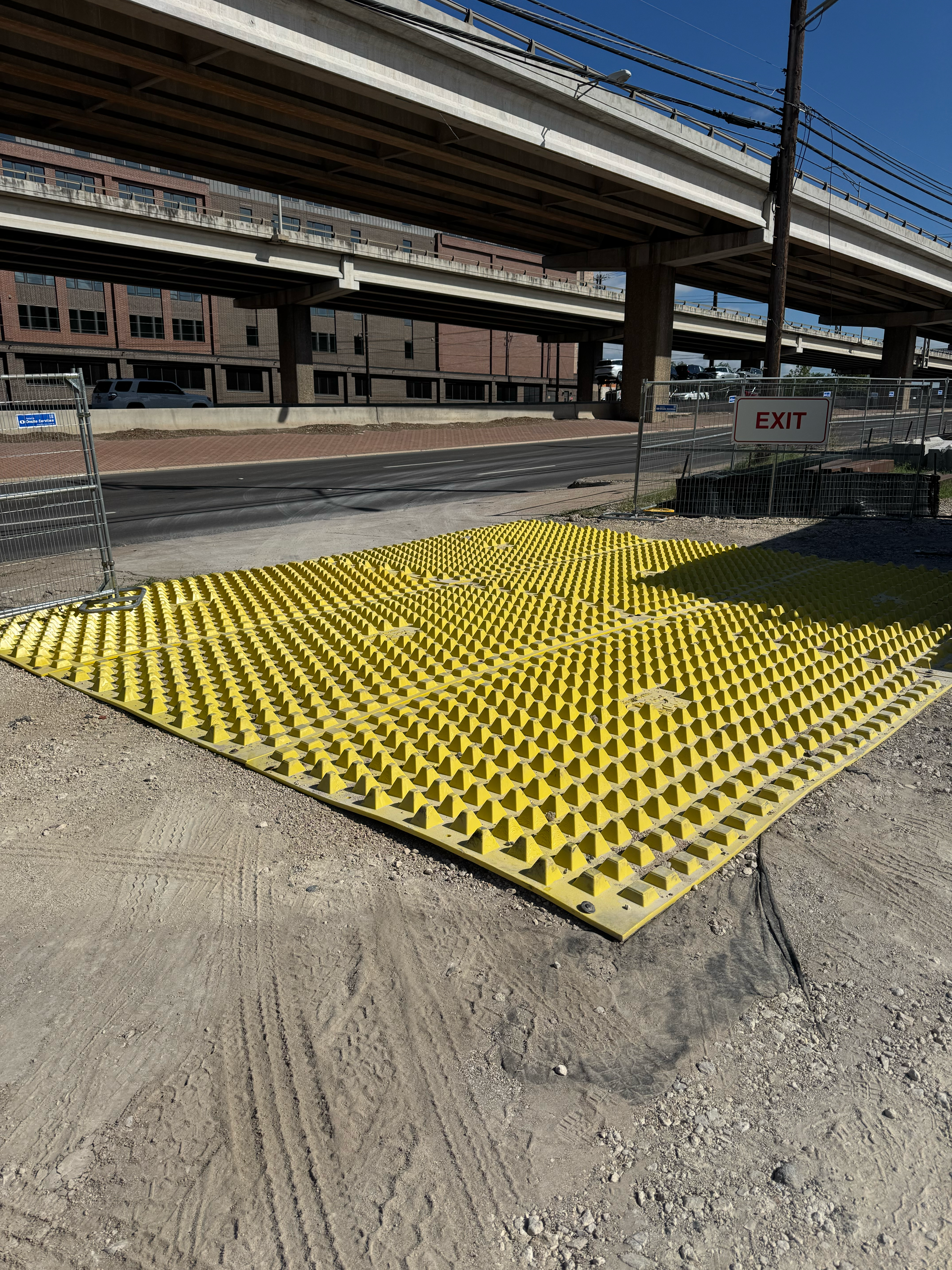

One of the most visible aspects of the project’s compliance strategy involves controlling trackout, the sediment and debris carried offsite by construction vehicles. In a dense downtown corridor, even small amounts of sediment can create safety hazards for motorists and pedestrians. To prevent this, SAK Construction installed FODS Trackout Control Mats at major access points.

FODS mats are reusable devices made from durable high-density polyethylene. Their raised pyramid design flexes vehicle tires, shaking loose sediment and debris before vehicles leave the site. The mats perform consistently across different soil and weather conditions, providing a cleaner and more reliable alternative to traditional rock entrances.

Unlike stone pads that require constant maintenance and replacement, FODS mats can be cleaned quickly and relocated as construction phases shift. This reduces material waste, eliminates repeated aggregate deliveries, and lowers the overall environmental footprint. The system also helps maintain cleaner public roads, improving community safety and minimizing complaints.

Regular inspections ensure that the mats and surrounding areas remain compliant with both TPDES and City of Austin watershed regulations. By integrating this approach, the project demonstrates how large-scale construction can meet stringent environmental standards without sacrificing productivity.

Project Team and Collaboration

Delivering a project of this magnitude requires collaboration across public and private sectors. TxDOT leads the program and coordinates with regional partners, including the Capital Area Metropolitan Planning Organization. The agency provides oversight, manages funding, and ensures that the drainage tunnels integrate with future phases of the I-35 reconstruction.

The SAK and J.F. Shea joint venture serves as the tunneling contractor. SAK brings national expertise in trenchless technology, while J.F. Shea contributes a long legacy of civil engineering experience dating back more than a century. Their combined skill set enables the team to navigate both the technical and logistical challenges of deep-bore tunneling in an urban environment.

Webber LLC, based in Houston, is constructing the Capital Express Central Drainage Pump Station. As part of the Ferrovial Group, Webber specializes in large civil and water infrastructure projects and integrates seamlessly with PLW Waterworks for mechanical and electrical systems.

Engineering partners include BGE Inc., which provides design, hydraulic, and alignment services, and Schnabel Engineering, which oversees geotechnical risk and structural stability. Together, the multidisciplinary team delivers a coordinated effort focused on safety, performance, and long-term reliability.

Construction Timeline and Economic Impact

Construction of the tunnel system began in May 2025, starting with priority shaft excavations along I-35 and Cesar Chavez Street. Tunneling operations will continue for approximately four years, with the entire drainage network expected to be complete by 2029.

Although the drainage system represents only one component of the broader $4.5-billion Capital Express Central program, it is arguably the most critical. Without it, the lowered highway reconstruction could not proceed safely. The system protects billions of dollars in infrastructure investment and mitigates flood risks that have historically impacted downtown Austin.

The project also delivers substantial economic benefits. It supports hundreds of skilled construction and engineering jobs and provides opportunities for local subcontractors and suppliers. Training initiatives and safety programs ensure that workers gain valuable experience in tunnel construction, an expertise increasingly needed across Texas.

In addition, the project’s focus on sustainability reduces waste and operational costs. Reusable systems such as FODS mats, efficient material handling, and phased excavation reduce the environmental footprint while improving cost efficiency over the life of the project.

Long-Term Benefits and Resilience

When complete, the SAK Tunnel Project will redefine how Austin manages stormwater. Modeling shows a dramatic reduction in surface flooding along I-35 and surrounding neighborhoods during major storm events. Depressed highway sections will remain open during heavy rain, protecting mobility for residents, commuters, and emergency services.

The system’s capacity also protects adjacent communities from runoff that once flowed into streets and neighborhoods. By diverting stormwater underground and releasing it through a controlled outlet, the tunnels prevent erosion, reduce property damage, and improve the quality of water entering the Colorado River.

From an operational standpoint, the system is designed for long-term resilience. Its size and redundancy allow it to handle both current and future rainfall projections, and its maintenance access points ensure that it can be inspected and serviced efficiently.

For TxDOT and the City of Austin, the project represents a model of proactive infrastructure design. By building the drainage foundation first, the state is setting a precedent for how transportation agencies can integrate climate adaptation into large public works.

Looking Ahead

As construction continues, the SAK Tunnel Project stands as one of the most ambitious stormwater infrastructure undertakings in Texas. It illustrates how engineering, environmental management, and community coordination can converge to create a more resilient city.

The project’s success reflects the dedication of TxDOT, its design and construction partners, and the people of Austin who have supported a long-term vision for sustainable growth. Once completed, the tunnels and pump station will operate quietly beneath the city, protecting downtown Austin from floods, supporting safe mobility, and ensuring that the Capital Express Central program achieves its promise.

The SAK Tunnel Project is not simply a drainage improvement. It is the invisible foundation of Austin’s future infrastructure, a testament to how thoughtful engineering can protect a city’s heart while preparing it for decades of continued growth and change.