Multiple FODS Entrances Deployed On $675M Caesars Virginia Project

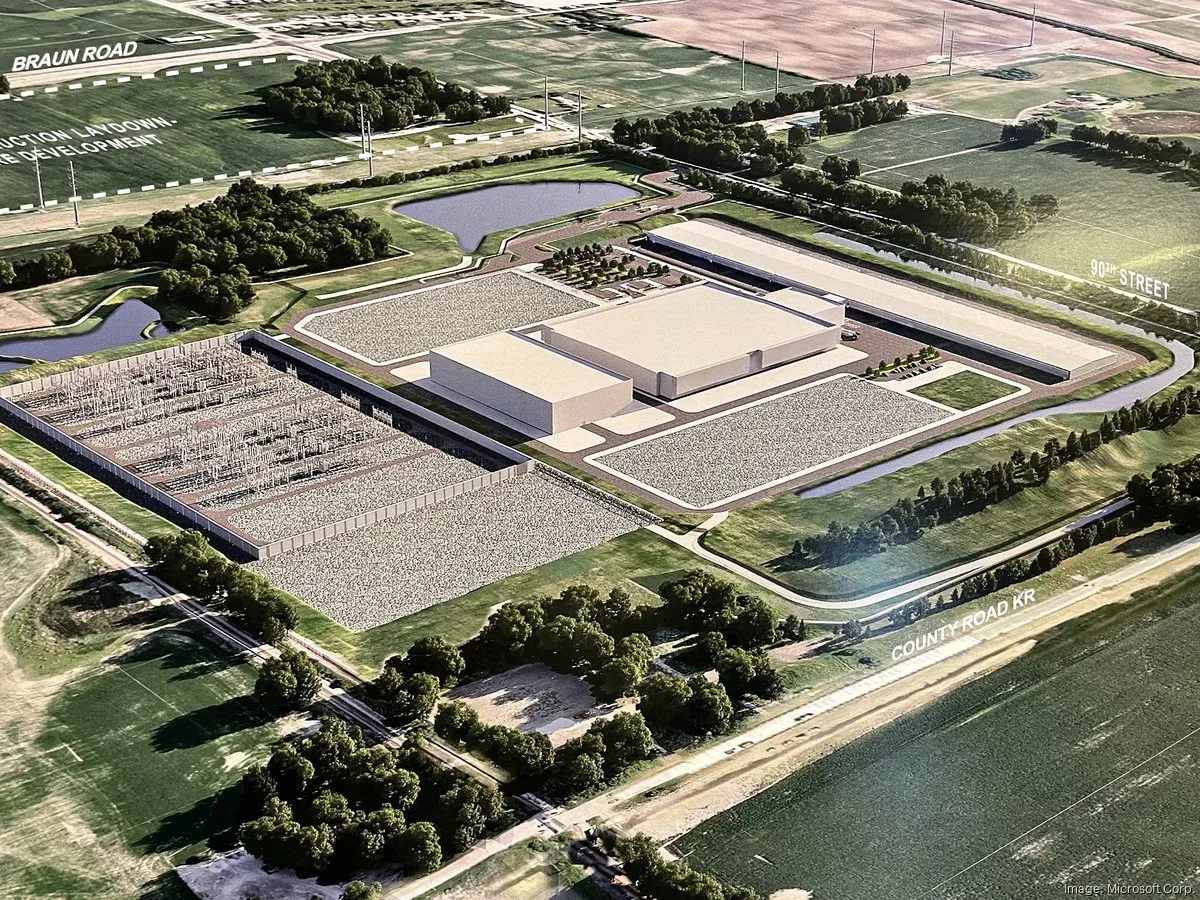

Nestled along the border of North Carolina and Virginia, on top of the old Dan Mills Textile Mill the city of Danville is preparing to welcome a groundbreaking $675 million casino development by the renowned Las Vegas based Caesars Entertainment. This state-of-the-art casino complex promises a luxurious experience, boasting 500 rooms, a World Series of Poker room, 40,000 square feet of meeting and convention space, a 2,500-guest entertainment venue, diverse restaurants and bars, a spa, pool, and fitness center. Such a significant endeavor requires a construction partner of the highest caliber, and the responsibility fell upon Whiting-Turner, a distinguished general contracting firm ranked fifth on ENR's top 400 contractors list. Renowned for their prowess in the hospitality and entertainment sector, Whiting-Turner's impressive portfolio includes projects like Caesars Palace in Las Vegas, the LINQ Hotel, and Harvey's Lake Tahoe. Upon completion, the casino is expected to create 900 jobs, thereby boosting the economies of Danville and its neighboring areas.

This site has a long history of industrial use in the textile industry and more recently the tobacco industry. The EPA has designated as a brownfield, which introduces unique requirements to mitigate contamination, but also brings technical support and financial opportunities from both local and federal agencies. The City of Danville has conducted multiple assessments to aid in financial planning of development projects, which will promote economic growth and facilitate the remediation of contaminants left over the textile manufacturing process which includes dyes, dry cleaning compounds and degreasing agents. The efforts of the local and federal agencies have created the right conditions for private developers transform these brownfield sites into major new attractions throughout the River District.

With these environmental challenges and opportunities in mind, Whiting-Turner set out to build the Caesar Casino with the industries leading best management practices (BMPs) and best in class solutions for mitigating environmental impacts. One of the first considerations is the construction site entrances and exits. Whiting-Turner turned their attention towards the FODS Trackout Control System as they have on many jobs. Over twice as effective as traditional rock entrances, the use of FODS Trackout Control System demonstrates a focus on environmental responsibility and economic management.

During the construction of the main casino, Caesars Entertainment established a 24/7 temporary tent casino to accommodate guests. Safety considerations for casino patrons were paramount, and keeping the roadways clear of sediment and debris helps to promote safety for patrons and through traffic alike. This is another benefit that the FODS Trackout Control System provides compared to traditional construction entrances. The deployment of FODS prevents the operators from laying rock at the site exits which can cause safety risks if they are ejected onto the roadway. With FODS, no rock is needed at the site exit points, which in turn leads to less debris on the roadway.

Manufactured using High-Density Polyethylene with UV treatment, the FODS Trackout Control Mats are exceptionally durable and adaptable to various environments. The installation process for a typical FODS entrance takes 30 minutes, minimizing downtime and ensuring swift setup for site entrances. These mats are designed to remove sediment, mud and other debris, from vehicle tires as they exit a construction site onto a paved surface. The conventional method of creating a stabilized construction entrance laying tons of stone for each entrance was time-consuming and less efficient. Considering this, the construction team sought an effective solution to expedite the construction process and ensure safety and cleanliness at the worksite. It was the obvious choice for a project of this scale. The unique staggered pyramid design separates tire treads, allowing rocks, dirt, and other debris to fall to the bottom of the mat where it does not contact vehicle tires. The design allows for continued performance on long term development and promotes safety at every exit. FODS does not require additional materials throughout the project which means both costs and performance are predictable.

The FODS Trackout Control Mat is the leading solution for keeping your projects on schedule, reduce costs, cutting out downtime, protecting the roadway, and keeping your site clean. The FODS Trackout Control Mat has proven invaluable in constructing the Caesars Entertainment casino project in Danville, Virginia. With its exceptional durability, easy installation process, and the ability to enhance safety and cleanliness on the worksite, the FODS Trackout Control Mat is the premier choice for construction exits.

Whiting-Turner’s use FODS Trackout Control System on this particular site underscores the systems effectiveness at containing debris. By choosing effective solutions, Whiting-Turner demonstrates a commitment to efficiency, safety, and environmental responsibility. The Caesars Entertainment casino project is a testament to the collaboration between cutting-edge construction techniques and visionary construction partners. As it paves the way for economic growth in Danville and surrounding areas, it also showcases the pivotal role played by products like the FODS Trackout Control Mat in shaping the future of construction projects of this scale and intricacy.

ABOUT FODS, LLC.

Based in Centennial Colorado, FODS is working to replace ineffective and costly traditional rock stabilized construction entrances, saving you time and money. Our proprietary mat design works to effectively remove debris from your vehicle tires without damaging the tire or the ground’s surface. We provide the only durable, reusable, and environmentally friendly trackout control system currently available on the market. FODS Vehicle Trackout Controls BMP mats are 100% Made In the USA and 100% recyclable.

To find out more information on how we can help your project stay on schedule and in compliance contact 844-200-3637 or email us at info@getfods.com.