Massachusetts Stabilized Construction Entrance

Massachusetts continues to set the standard in the northeast and nationally for balancing infrastructure growth with environmental protection. In a state renowned for its significant infrastructure projects, such as the "Big Dig," ongoing work in the dense innovation hubs of Cambridge and Boston, and the expanding transportation corridors along I-95, construction activity across the Commonwealth necessitates careful management of erosion, sediment, and stormwater runoff. With more than 3,000 freshwater lakes and hundreds of miles of rivers, Massachusetts' waterways are vital to both the state's ecological health and the well-being of its communities. Protecting these resources means enforcing strict requirements for stabilized construction entrances, ensuring mud, soil, and debris from active sites do not reach public roadways or storm drains.

Massachusetts State Standards and NPDES Permits

The foundation of Massachusetts' stormwater management framework lies in the Clean Water Act (CWA), which authorizes the U.S. Environmental Protection Agency (EPA) to regulate the discharge of pollutants through the National Pollutant Discharge Elimination System (NPDES) program. The Commonwealth operates under joint oversight by EPA Region 1 (New England) and the Massachusetts Department of Environmental Protection (MassDEP), ensuring that both federal and state environmental standards are met.

MassDEP enforces stormwater protection through the Wetlands Protection Regulations (310 CMR 10.00), which safeguard groundwater, drinking water supplies, floodplains, and wildlife habitat. These regulations complement the Massachusetts Stormwater Management Standards, which require projects to control runoff volume and velocity, remove sediment, and prevent pollutants from entering natural waterways. Every construction project, whether a mixed-use redevelopment in downtown Boston or a bridge reconstruction along the Turnpike, must integrate effective Best Management Practices (BMPs) for sediment control.

Among these BMPs, the Stone Stabilized Pad Construction Entrance remains one of the most critical tools for controlling off-site sediment transport. It represents the first line of defense against construction site trackout that can cause roadway hazards, storm drain blockages, and non-compliance under the Massachusetts NPDES Construction General Permit (CGP).

2017 Massachusetts Construction General Permit (CGP)

Construction sites disturbing one acre or more must obtain NPDES coverage under the EPA 2022 Construction General Permit before disturbance begins. This permit requires operators to prepare a Stormwater Pollution Prevention Plan (SWPPP) detailing all potential sources of pollution, identifying BMPs, and describing inspection and maintenance procedures.

The SWPPP serves as a living document, guiding contractors on how to minimize sediment discharge and respond to rain events. Stabilized entrances are typically installed before excavation begins and remain in place until the final stabilization is complete. They prevent soil from adhering to tires and being carried onto paved surfaces, one of the most visible and enforceable aspects of stormwater compliance in Massachusetts.

For urban sites like the Kendall Square redevelopment outside of Boston in the SoMa district of Cambridge, where construction activity occurs adjacent to public sidewalks and active traffic, the stabilized entrance also serves as a safety and cleanliness measure, preserving air quality and reducing slip hazards. In large-scale infrastructure projects such as the recent I-95 expansion, multiple access points may be required throughout sequential construction phases, making durability and reusability critical performance factors.

MassDEP Standard: Stone-Stabilized Construction Entrance

A temporary stone-stabilized pad is located at points of vehicular ingress and egress to reduce mud and sediment displacement. This technique is effective when all vehicle traffic is restricted to stabilized entrances and exits. The MassDEP Erosion and Sediment Control Practices Guide describes a standard stone-stabilized pad construction entrance.

The Guide states that the entrance should be installed with a positive grade so runoff will flow back towards the construction site and away from the paved road surface. The stone pad consists of a Geofabric topped with 6 inches of aggregate, ranging in size from 1 to 3 inches. The length of the entrance should be a minimum of 50 feet, or 30 feet for residential lots, but may need to be extended if the entrance does not provide adequate containment of sediment. If the vehicle's action on the gravel pad is still insufficient to remove most of the mud, the tires must be washed before entering a public road. If washing is used, a sediment trap must intercept the wash water and trap the sediment before it is carried off-site. Inadequate runoff control is a common problem that causes dirt and mud to be washed onto public roads.

This type of construction entrance requires upkeep to maintain effectiveness. After the rock becomes compacted or after a rain event, the stone pad should be redressed with additional aggregate to restore its efficacy. When the work is complete, the stone entrance must be removed, and the areas must be prepared for final stabilization.

FODS Track Out Mat System: A Modern, Rockless Solution

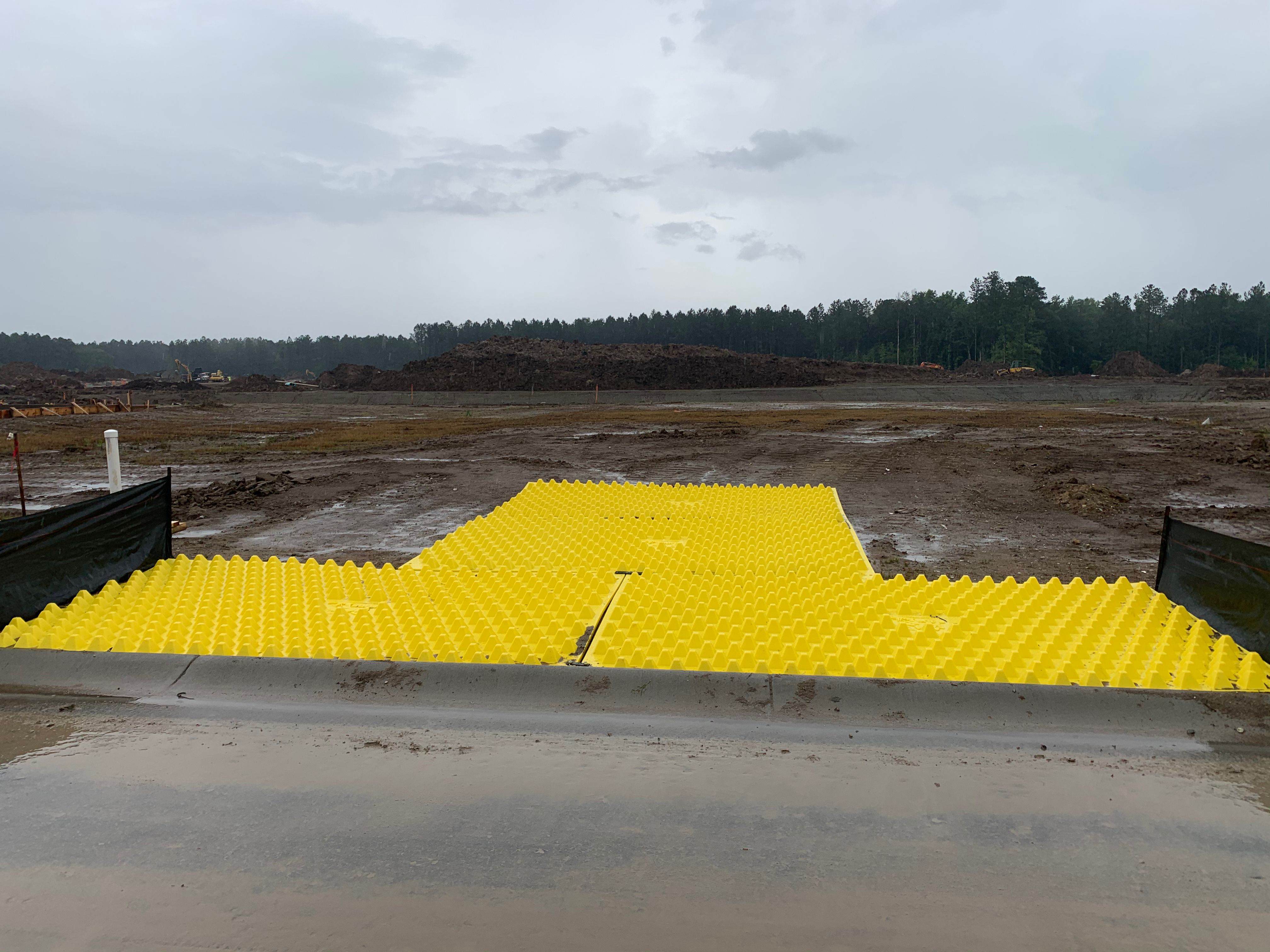

The FODS Trackout Control Mat System provides a durable, reusable, and environmentally superior alternative to traditional stone pad entrances. Constructed from high-density polyethylene (HDPE), FODS mats feature a patented pyramid-pattern surface that flexes tire treads to dislodge compacted soil, mud, and gravel. This mechanical cleaning action prevents sediment from leaving the site while eliminating the need for aggregate material.

Field testing and real-world use demonstrate that FODS mats are 60-80% more effective at removing sediment than conventional rock entrances, resulting in a significant reduction in street sweeping. Because the mats are portable and modular, they can be deployed on soil, gravel, asphalt, or concrete without extensive site preparation. Installation typically requires only basic anchoring hardware, and maintenance involves sweeping the mats using a skid steer with a broom attachment or manual removal using the FODS Cleanout Shovel; no refreshing, re-rocking, or replacement is required.

At Kendall Square in Cambridge, where construction took place adjacent to biotech campuses and research facilities, FODS mats were selected due to their demonstrated ability to reduce dust, maintenance, and material deliveries associated with traditional rock entrances. Their clean, low-profile design helped contractors maintain compliance while minimizing disruption in a high-traffic urban setting. The bright "Safety Yellow" color of the mat clearly denotes to drivers the proper entry and exit point for the construction site. Similarly, during the I-95 expansion project, FODS mats provided a portable trackout solution for multiple phases of roadway widening and utility relocation. Crews were able to relocate the mats quickly between work zones, thereby avoiding the need to import and dispose of thousands of pounds of aggregate continuously.

Environmental and Economic Benefits

By eliminating the need for stone, the FODS Track Out Mat System drastically reduces the environmental footprint associated with stone-stabilized pad construction entrances. Traditional aggregate pads require quarrying, hauling, and disposal, each phase generating greenhouse gas emissions and roadway wear. Reusable HDPE mats avoid this cycle, aligning with Massachusetts' sustainability goals and the MassDEP Waste Reduction Program.

From an economic standpoint, contractors realize long-term savings through lower maintenance and material costs. Once purchased, FODS mats can be reused across multiple projects for over a decade, resulting in a significantly lower cost per entrance over time. They also reduce downtime during wet weather, as the mats can be refreshed in minutes rather than hours.

Projects that employ FODS systems report measurable improvements in compliance outcomes. Clean exit points mean fewer trackout citations, reduced street sweeping costs, and improved relationships with local inspectors and surrounding communities. For sensitive urban sites, such as SoMa, or for multi-phase infrastructure programs like I-95, those advantages translate directly into smoother project delivery and reduced operational risk.

Regulatory Alignment and Compliance

Under the Massachusetts NPDES Construction General Permit, stabilized entrances are a required element of every Stormwater Pollution Prevention Plan. FODS mats meet the functional intent of this requirement as FODS is a structural Best Management Practice (BMP) designed to prevent the discharge of sediment and debris from vehicle tires. The FODS Track Out Mat System fully supports the compliance goals outlined by both EPA Region 1 and MassDEP, including maintaining stabilized access points, minimizing pollutant discharge, and documenting consistent BMP performance throughout the construction process.

Because FODS mats are rockless, they eliminate the uncertainty that often arises during inspections over whether stone pads are adequately maintained. Inspectors can clearly verify function and condition in a single visit, improving transparency and efficiency. For contractors, this consistency reduces the likelihood of negative enforcement actions, change orders, or rework, which regularly stem from failed BMP performance.

Widespread Adoption Across Massachusetts

The nationwide success of FODS has encouraged its use on other projects throughout the state, including municipal public works and private industrial developments. In densely populated areas, FODS mats have proven especially valuable where limited space makes traditional aggregate pads impractical or disruptive. Their clean, reusable design also complements Massachusetts' broader push toward low-impact development (LID) and green infrastructure principles.

Engineering firms, general contractors, and environmental compliance managers across Massachusetts are increasingly specifying the FODS Track Out Mat System in their project SWPPPs. Many now view FODS as a standard component of site access planning, particularly where project schedules, cost efficiency, and sustainability goals intersect.

Massachusetts has long been a leader in stormwater management, from its early wetlands protection laws to today's advanced construction permitting framework. As infrastructure and urban redevelopment continue to expand, the tools used to achieve compliance are also evolving.

The FODS Track Out Mat System represents innovation and the next generation of stabilized construction entrance technology, offering superior sediment removal performance, reusability, and environmental sustainability. Proven on high-profile projects worldwide, FODS provides contractors with a cleaner, safer, and more cost-effective method of managing trackout, while fully meeting EPA Region 1 and MassDEP requirements.

By replacing disposable stone entrances with reusable FODS mats, contractors reduce waste, streamline maintenance, and uphold the Commonwealth's commitment to protecting its most valuable resource, clean water. The result is a practical, forward-looking solution that supports both regulatory compliance and the environmental legacy that defines Massachusetts.

Additional Resources:

Construction Entrance Resource

EPA Construction General Permit (2017)

Massachusetts Stormwater Handbook and Stormwater Standards

Massachusetts Stormwater Handbook Vol 2, Ch 2, Stormwater Best Management Practices

Stormwater Management - MassDOT Environmental Services

EPA Stormwater Discharges from Construction Activities