A modular trackout control system developed by FODS, LLC was used to support underground boring operations along the Central Tri-State Tollway (I-294), where contractors are installing new fiber-optic communications infrastructure as part of a broader modernization program led by the Illinois Tollway Board of Directors and the Illinois Department of Transportation (IDOT).

The system, supplied by Brock White Construction Materials and deployed by Old Veterans Construction (OVC), has been introduced as a reusable alternative to traditional gravel tracking pads which make up the Stabilized Construction Entrance which historically have been specified by the Illinois Department of Transportation (IDOT). Its purpose is to prevent sediment and debris from being carried onto the active roadway during ongoing directional drilling and utility installation activities that parallel one of the busiest highway corridors in the Midwest.

Upgrading the Communications Backbone of I-294

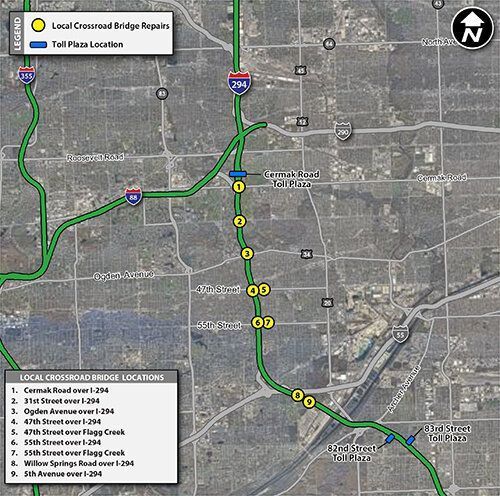

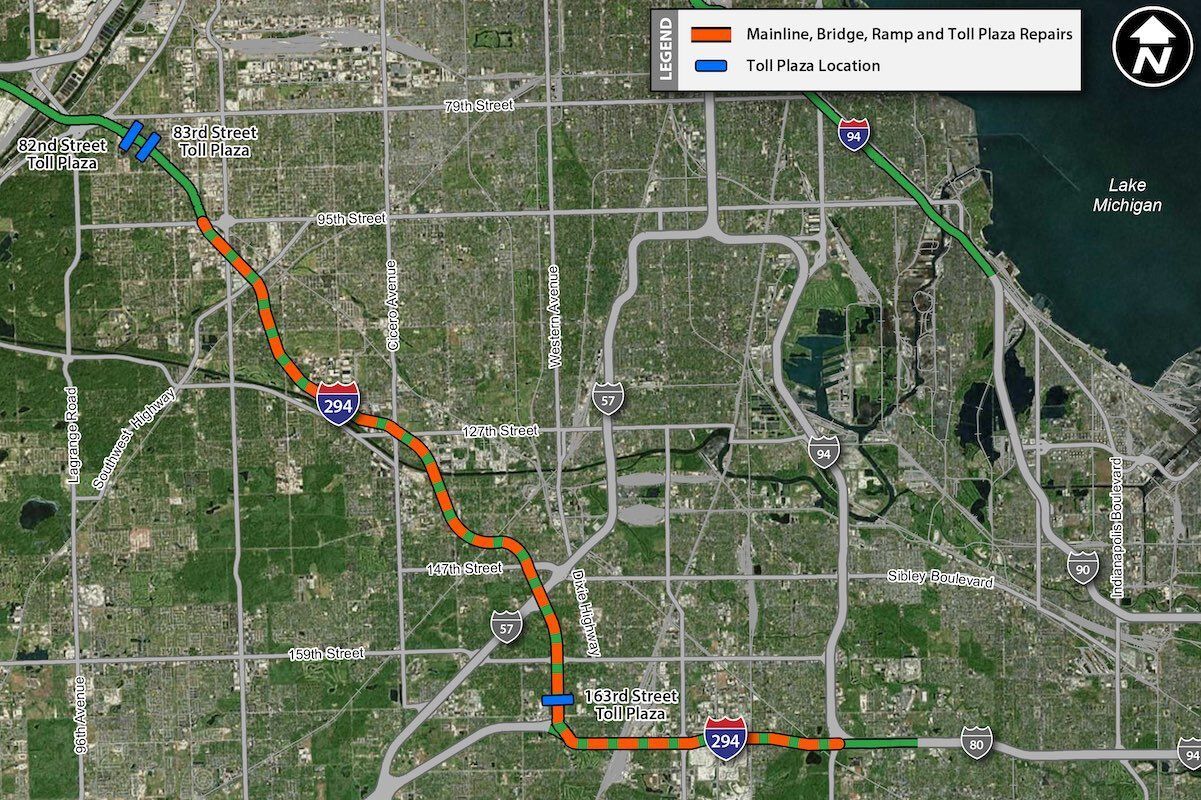

The fiber-optic work forms a key component of the Tollway’s long-term “SmartRoad” initiative, which aims to enhance real-time traffic management, lane control, and connected-vehicle capabilities. The project calls for the installation of high-capacity conduit and fiber lines along dozens of miles of the Central Tri-State corridor between 75th Street and O’Hare International Airport.

Much of the work involves horizontal directional drilling (HDD) and auger boring to install conduit beneath the highway shoulders and median areas without disrupting traffic flow. Crews are operating in narrow work zones that shift incrementally as each bore is completed conditions that require frequent mobilization of equipment and repeated setup of stabilized construction access points.

These types of linear boring operations require contractors to establish and relocate temporary entrances almost continuously, every time the team moves to a new bore pit or pullback area, they have to manage vehicle egress in a way that keeps mud and slurry from reaching the pavement.

Trackout Control Challenges in Boring Operations

Directional drilling and auger boring produce a unique set of byproducts that complicate erosion and sediment control. Spoils and bentonite-based drilling slurry can accumulate around bore pits and exit points, quickly coating construction equipment and truck tires. When construction vehicles and equipment leave these areas to enter paved haul routes, the material is easily tracked onto public roads, creating potential safety hazards and violating stormwater regulations under the National Pollutant Discharge Elimination System (NPDES) program.

Historically, contractors have mitigated this risk by constructing stabilized construction entrances with gravel pads at each access location. While this method has long been used, gravel pads are time-intensive and costly, particularly when used in mobile trenchless operations. Each pad requires excavation, placement of filter fabric, and importation of aggregate followed by removal and disposal once work advances. With dozens of bore locations spaced along miles of highway right-of-way, this traditional approach can add days of cumulative labor and thousands of dollars in recurring material costs.

Furthermore, the confined geometry of many access sites often positioned the working crew adjacent to live traffic lanes, guardrails, or drainage ditches limits available space for full-length rock entrances. These constraints led OVC to evaluate alternative solutions that could provide equivalent or better performance while allowing faster deployment between work fronts.

Portable Mat System Selected

After reviewing multiple options and due to a condensed project schedule, OVC selected the FODS Trackout Control System, a modular, reusable mat constructed of high-density polyethylene (HDPE) and engineered specifically for construction vehicle trackout mitigation. Each FODS mat features a series of raised, staggered pyramids that mechanically flex tire treads as vehicles pass over, dislodging accumulated mud, bentonite, or debris. The system operates without the need for loose aggregate and can be installed directly on soil, asphalt, or concrete surfaces.

For the I-294 boring operation, OVC crews utilized FODS mats at exit points along the drilling alignment, relocating them as the work advanced.The portability of the mats also reduced the environmental footprint of the operation. Unlike rock entrances, which must be rebuilt for each new setup, the same FODS units were reused repeatedly, minimizing waste and material transport. The team at OVC relayed to Brock White that they created 60-different construction entrances with the FODS mats over the course of 90-daysl.

Regulatory and Safety Considerations

Under the Illinois EPA’s Construction Stormwater Permit, contractors are required to implement Best Management Practices (BMPs) that prevent pollutants including sediment and drilling fluids from leaving the project boundary. The state’s erosion and sediment control manual recognizes “stabilized construction entrances” as a primary BMP for managing vehicle trackout. The FODS system meets and exceeds these requirements by providing a stabilized surface capable of effectively removing soil from tires while preventing deposition onto pavement.

In addition to meeting environmental standards, the system contributed to jobsite safety. The absence of loose stone eliminated the risk of aggregate spillage onto active lanes an important consideration in the restricted shoulder work zones that characterize the I-294 corridor. As any contractor on a heavy civil highway construction project knows, any rock that makes its way into traffic becomes a hazard. By using a composite construction entrance system which is rockless, FODS eliminates this source of protentional liability for the contractor.

Performance in Field Conditions

During the installation phase, crews observed several operational advantages:

- Rapid Installation and Removal: Each construction entrance less than 30 minutes to install using a skid steer or small excavator. No excavation, filter fabric, or aggregate hauling was required.

- Adaptability to Varying Substrates: Mats were placed directly on existing gravel shoulders and compacted subgrade, maintaining stability even under heavy truck loading.

- Effective Sediment Removal: The raised-pyramid geometry dislodged wet drilling spoils that typically remain embedded in tire treads when using gravel pads.

- Ease of Cleaning: Collected material is removed using either a skid-steer with broom attachment or a FODS Cleanout shovel.

- Reusability: The mats were redeployed at successive bore sites again and again, eliminating repetitive procurement and wasteful disposal.

The system’s ability to perform consistently across multiple soil conditions including cohesive clay and fine sand proved valuable as the fiber alignment is forced to traversed varying geological zones. With crews advancing through each segment in rapid, short durations, the ability to relocate FODS trackout control Mats quickly supported overall project scheduling.

Environmental and Economic Outcomes

From both environmental impact and cost perspectives, the results were measurable. OVC reported eliminating the import and removal of aggregate at more than 60 temporary access points, saving an estimated $4,500–$5,000 per location in coarse aggregate (CA-1 through CA-4) material hauling, and disposal costs. Labor hours associated with pad construction and removal were also reduced significantly.

Beyond the economic benefits, the shift to a reusable system supported the Tollway’s broader sustainability objectives. Each FODS mat is manufactured in the United States from HDPE, incorporates recycled material and is completely recyclable and has an estimated service life of 10 years, allowing it to be reused across multiple projects before eventual recycling. This lifecycle approach aligns with state initiatives promoting reduction of construction waste and adoption of durable materials.

Alignment with Industry Trends

The deployment along I-294 reflects a broader movement toward portable, modular sediment control technologies in the trenchless and utility construction sectors. As fiber-optic and broadband expansion accelerates nationwide, contractors face similar logistical challenges tight work areas, frequent mobilizations, and strict stormwater compliance requirements.

Several state transportation agencies, including Caltrans, Washington State DOT, and Michigan EGLE, have already integrated modular trackout mats into their BMP libraries as approved alternatives to rock entrances. The Illinois Tollway’s environmental management team is monitoring performance data from ongoing installations to evaluate broader applications in future projects.

Broader Project Context

The fiber-optic installation is one of several parallel efforts contributing to the Tollway’s overall modernization of I-294. In addition to roadway reconstruction, bridge widening, and drainage improvements, the new communication backbone will enable variable speed limits, digital signage, and data-sharing between traffic management centers and connected vehicles.

Trenchless construction methods such as HDD and auger boring have been instrumental in minimizing surface disruption. By allowing utilities to be installed beneath the pavement without open excavation, these techniques reduce lane closures and shorten construction durations. The integration of reusable trackout controls complements that approach by minimizing aboveground environmental disturbance.

Outlook

As OVC continues progressing north along the corridor, FODS mats remain in rotation—deployed, cleaned, and redeployed across dozens of bore locations. The contractor expects to complete its portion of the fiber-optic alignment by early next year.

Project engineers indicate that the system’s performance has met or exceeded expectations in maintaining clean pavement conditions adjacent to active work zones. Given those results, the technology is likely to see continued use in similar utility and infrastructure projects where mobility, compliance, and efficiency intersect.

Thank you to Old Veterans Construction and Brock-White for your help on this project.

About FODS

Based in Englewood Colorado, FODS Trackout Control System replace ineffective and costly traditional rock stabilized construction entrances, saving you valuable time and money. Our proprietary mat design works to effectively remove mud and sediment from your vehicle tires without damaging the tire or the ground’s surface. We provide the only durable, reusable, and environmentally friendly trackout control system currently available on the market. FODS Trackout Control Mats are 100% Made in the USA and are reusable and recyclable.